1997

Founded in 1997

28000㎡

Factory Area

200+

Current Employees

20+

Years’ R&D Experience

Household Appliance Carbon Brushes

Power Tools Carbon Brushes

Automotive Parts Carbon Brushes

Industrial Machinery Carbon Brushes

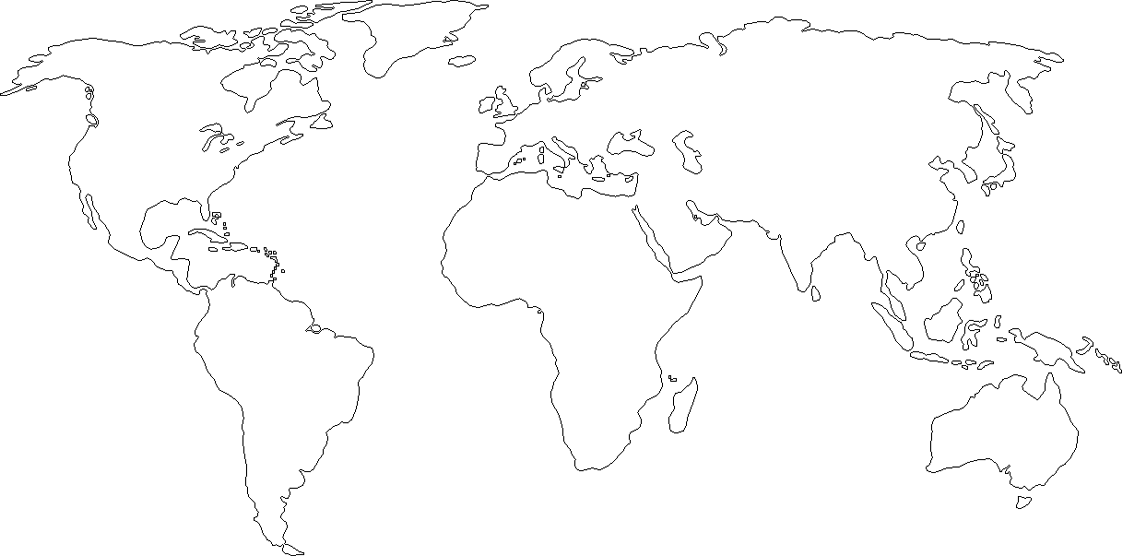

China

Venezuela

Ecuador

Brazil

Peru

Chile

Argentina

Morocco

Türkiye

Israel

Egypt

Iran

United Arab Emirates

Palestine

India

Thailand

Vietnam

Malaysia

Singapore

Philippine

Indonesia

Russia

South African Republic

Australia

The US