How to determine if the common automotive motor carbon brushes have worn down to the point where replacement is necessary?

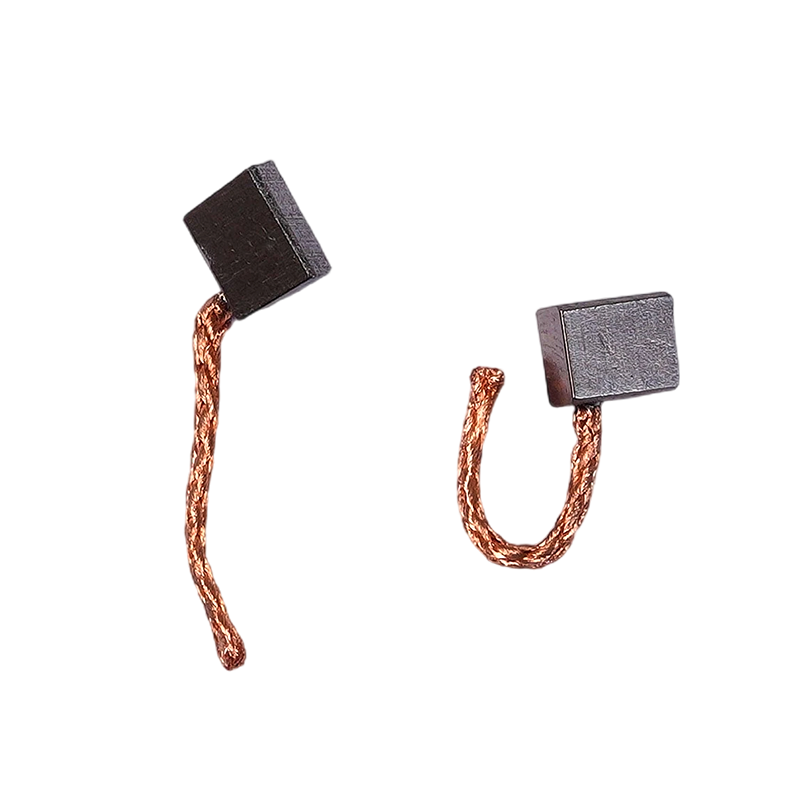

Visual Inspection of Brush Length in common automotive motor carbon brushes

Determining whether common automotive motor carbon brushes require replacement often begins with visual inspection. As carbon brushes operate against the commutator, they gradually shorten. Each automotive motor design specifies a minimum safe length below which brush performance cannot remain stable. When the brushes approach this threshold, contact pressure decreases, electrical conduction becomes irregular, and the likelihood of sparking increases. Jiangsu Hailing Carbon Products Co., Ltd., with its refined production methods and advanced ERP-based control, manufactures carbon brushes with consistent density and wear patterns, making length assessment more predictable for technicians. Brush holders used in automotive starters, cooling fan motors, or window lift motors typically allow easy access for checking the remaining brush length, helping users judge whether further operation may risk unstable performance.

Changes in Motor Performance During Vehicle Operation

Another key method for identifying wear in common automotive motor carbon brushes is monitoring motor behavior. When brushes become heavily worn, electrical transfer efficiency declines, resulting in slow motor response, reduced torque output, or intermittent startup. For example, starter motors may require multiple attempts to engage, while blower motors might run at inconsistent speeds. These operational symptoms often indicate that contact with the commutator is no longer stable. Jiangsu Hailing Carbon Products Co., Ltd., which has long collaborated with domestic and international automotive motor manufacturers, produces brushes tailored to ensure stable conduction throughout their intended lifespan. When performance changes appear, they can serve as early signs that the brushes have reached a point where replacement becomes necessary.

Noise, Sparking, and Abnormal Smells as Wear Indicators

Excessive noise or visible sparking can signal that common automotive motor carbon brushes have worn down. As the brush tip becomes too short or uneven, contact pressure becomes irregular, causing small arcs between the carbon brush and the commutator. This may produce a burning smell or faint electrical odor, especially during high-current operation such as activating a vehicle’s starter or running high-speed fans. Jiangsu Hailing Carbon Products Co., Ltd., certified under ISO 14001 and ISO 45001, conducts environmental and durability testing to optimize brush material behavior. These tests help ensure that Hailing’s products maintain stable surface film formation, reducing unwanted noise or sparking. When these signs appear consistently, they often indicate that brush wear has surpassed safe limits.

| Symptom |

Possible Relation to Brush Wear |

| Frequent sparking |

Irregular contact caused by short or uneven brush tips |

| Burning smell |

Heat buildup due to poor conduction |

| Sharp mechanical noise |

Brush vibration or misalignment during operation |

Condition of the Commutator Surface After Continuous Operation

The commutator surface can also provide insight into the wear condition of common automotive motor carbon brushes. As brushes wear unevenly or lose stability, the surface film on the commutator becomes inconsistent. Technicians may observe discoloration, streaks, or rough copper segments. These changes typically result from unstable contact pressure and indicate that the carbon brush material has reached a point where reliable performance is no longer possible. Jiangsu Hailing Carbon Products Co., Ltd., recognized as a High-Tech Enterprise with IATF 16949 certification, applies advanced process control during manufacturing to maintain uniform material structure. This ensures the brushes work harmoniously with commutators for longer periods, allowing surface changes to be used reliably as diagnostic markers.

Spring Pressure Reduction and Its Impact on Brush Wear Assessment

As common automotive motor carbon brushes become shorter, the spring mechanism responsible for maintaining pressure weakens. Reduced pressure results in unstable contact and accelerated surface wear on both the brush and commutator. If a technician notices that the spring no longer exerts sufficient force, even when the brush still has some remaining length, replacement may already be necessary. Jiangsu Hailing Carbon Products Co., Ltd. engineers brush assemblies with carefully controlled spring performance to ensure predictable pressure over the lifespan of the carbon brushes. This consistency helps automotive technicians better identify when decreased pressure is caused by wear instead of structural variation.

| Spring Condition |

Effect on Brush Operation |

| Normal tension |

Stable electrical and mechanical contact |

| Reduced tension |

Irregular contact and increased sparking |

| Damaged spring |

Immediate need for replacement |

Electrical Testing and Diagnostic Evaluation

In some automotive repair environments, technicians use multimeters or diagnostic tools to determine whether common automotive motor carbon brushes have worn to critical levels. Increased electrical resistance, inconsistent current flow, or voltage drops during startup often suggest brush surface degradation. As Hailing’s carbon brushes are produced through refined machining and uniform material blending, their normal operating electrical characteristics remain stable throughout most of their service life. When diagnostic values deviate from expected ranges, it typically indicates that wear has progressed to a point where replacement is advisable.

Performance Stability as Verified Through Hailing’s Manufacturing Practices

Brush wear assessment becomes more accurate when the components are manufactured with consistent quality. Jiangsu Hailing Carbon Products Co., Ltd. applies its advanced ERP system, lean management strategy, and full-process ISO 9001 quality control to maintain uniform performance across each batch of common automotive motor carbon brushes. This consistency allows automotive service centers to rely on predictable wear patterns when determining replacement timing. The company’s commitment to innovation ensures that the brushes maintain stable contact and electrical conduction until they reach their designed wear limit.

Operational Environment and Its Influence on Brush Replacement Timing

Harsh environmental conditions, such as dust, temperature extremes, and moisture exposure, can accelerate brush wear. Common automotive motor carbon brushes used in wiper motors, fuel pumps, or ventilation blowers may face different environmental loads depending on vehicle use. Jiangsu Hailing Carbon Products Co., Ltd., with its international partnerships and industry certifications, designs brush materials that maintain stable operation across varied environments. When environmental factors cause wear to progress faster than expected, technicians may need to replace brushes earlier than standard maintenance intervals. Observing accumulated contamination or corrosion inside the brush chamber can be a practical indicator of accelerated wear.

How do common automotive motor carbon brushes maintain stable contact in a vibrating environment?

Structural Stability Design of common automotive motor carbon brushes

Ensuring stable contact for common automotive motor carbon brushes in a vibrating environment begins with structural design that accommodates motion, load variation, and continuous mechanical stress. Jiangsu Hailing Carbon Products Co., Ltd., with over two decades of carbon brush manufacturing experience and certifications such as ISO 14001, ISO 45001, and IATF 16949, emphasizes material formulation and structural optimization to support stable contact in dynamic conditions. For automotive motors that operate under frequent vibration, the carbon brush structure must include a uniform density matrix, controlled hardness, and reliable graphite-metal composition to help reduce contact interruptions. Such structural consistency makes the conductive path more reliable, even if the motor experiences shaking or abrupt driving conditions. Hailing’s independent innovation capabilities and advanced production equipment contribute to achieving stable structure performance that supports the long-term functionality of common automotive motor carbon brushes.

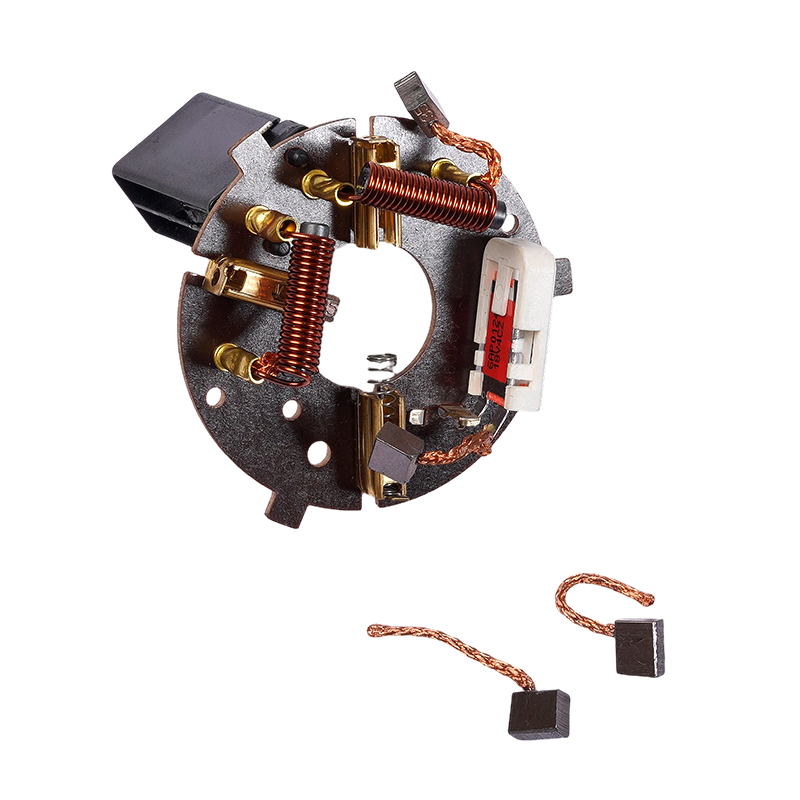

Role of Spring Pressure in Maintaining Continuous Contact

Spring pressure provides the core force that maintains the contact interface between common automotive motor carbon brushes and the commutator. In a vibrating environment, insufficient or unstable pressure can lead to intermittent gaps, sparking, or reduced efficiency. Hailing’s full-process quality control system, implemented in accordance with ISO 9001, ensures that spring assemblies match the brush dimensions and friction characteristics. Appropriate pressure counteracts vibration-induced displacement while avoiding excessive wear. When the spring force is balanced with the brush friction coefficient, the contact surface remains steady even if the motor experiences harsh road conditions. Automotive applications require tight tolerances, and Hailing’s ERP-managed production system helps ensure batch consistency of springs and brush holders, supporting reliable contact force across prolonged use.

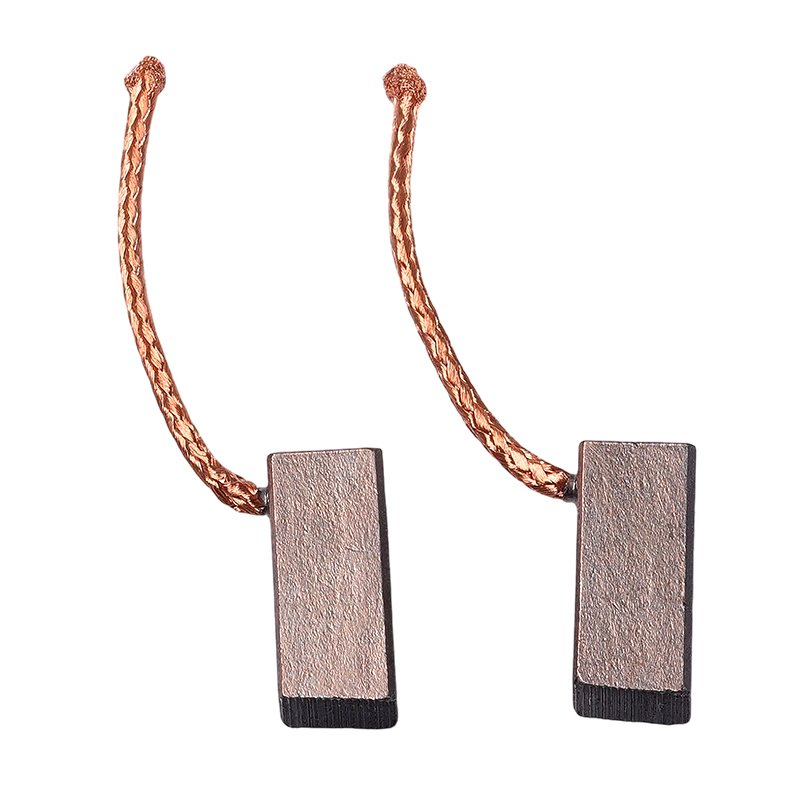

Material Selection and Wear Resistance under Continuous Vibration

Material formulation directly influences the ability of common automotive motor carbon brushes to maintain stable contact while the motor undergoes vibration. A well-selected carbon-based material prevents micro-cracks, surface flaking, or uneven wear, all of which could compromise the brush-commutator interface. Jiangsu Hailing Carbon Products Co., Ltd. employs material research supported by high-tech enterprise qualifications, enabling compositions that resist shock-induced deformation. For automotive motors that often run for long periods, consistent material density and controlled porosity help stabilize the friction film on the commutator. This steady friction film protects the interface from vibration-induced degradation, reducing the chance of contact loss or unstable electrical transmission.

Brush Holder Precision and Its Effect on Stability

The brush holder ensures that common automotive motor carbon brushes move smoothly while remaining properly aligned. In a vibrating environment, a poorly aligned brush holder may cause side wear, tilting, or intermittent contact. Precision machining and quality inspection contribute to an effective holder design that supports consistent linear movement. With Hailing’s advanced equipment and continuous improvement practices, brush holders used in automotive motors can achieve tighter tolerances and improved durability. A precise holder also reduces friction variability, allowing the brush to respond correctly to spring pressure and maintain steady contact with the commutator.

Electrical Stability and Commutation Consistency

Stable electrical performance is essential for maintaining reliable contact in vibrating conditions. Variations in contact resistance can interfere with current flow and cause irregular commutation. Jiangsu Hailing Carbon Products Co., Ltd. implements material testing, surface treatment, and inspection processes designed to maintain electrical stability. The consistent friction film formation between the brush and commutator assists in stabilizing resistance over time. This stability supports uniform current distribution, reducing the risk of sparking or noise during operation. In automotive motors where vibration is constant, electrical stability helps the brushes maintain continuous and predictable commutation behavior.

Environmental Factors Affecting Contact in Vibrational Use

Automotive environments expose common automotive motor carbon brushes to dust, humidity, temperature changes, and mechanical shock. These environmental variables may influence contact quality, especially when combined with vibration. Dust accumulation can cause uneven friction, while temperature shifts may impact material hardness or lubrication properties. Hailing’s adherence to ISO 14001 environmental standards supports the development of carbon brushes that maintain stable performance across varying conditions. Independent research also enables the use of additives or formulations that preserve surface stability under changing temperatures and environmental loads.

| Factor |

Influence on Contact Stability |

Effect Level Under Vibration |

| Spring Pressure Uniformity |

Determines consistent force on the commutator surface |

High |

| Material Composition |

Influences wear resistance and friction film stability |

High |

| Holder Precision |

Maintains alignment and reduces side wear |

Medium to High |

| Environmental Exposure |

Impacts lubrication and electrical consistency |

Medium |

| Electrical Load Variability |

Affects thermal stability and commutation behavior |

Medium |

Quality Control and Traceability Supporting Stable Contact

Traceability and batch consistency are essential for ensuring that common automotive motor carbon brushes behave reliably in high-vibration environments. Jiangsu Hailing Carbon Products Co., Ltd.’s ERP system allows full tracking from raw material procurement to final inspection. This traceability helps automotive manufacturers maintain confidence in product reliability. Certifications such as IATF 16949 reinforce production discipline, ensuring predictable brush performance even in demanding conditions. Stable contact is supported not only by design but also by process consistency, which is a core advantage for automotive motor applications.

Importance of OEM Collaboration for Vibration-Resistant Design

Close cooperation with automotive motor manufacturers allows better customization of common automotive motor carbon brushes to real-world operating conditions. Hailing’s partnerships with domestic and international motor brands enable continuous optimization based on field feedback. By understanding typical vibration patterns, load cycles, and installation conditions, the company can tailor brush formulations, spring settings, and holder design to improve stability. This industry collaboration enhances the ability of brushes to maintain contact, contributing to dependable performance in vehicles exposed to a wide range of mechanical stresses.

English

English 中文简体

中文简体