Key Environmental Challenges Affecting Design

Automotive fan and condenser carbon brushes face one of the most demanding operating environments in modern vehicles. Unlike industrial motors, these components must withstand rapid temperature fluctuations, high-intensity vibration, and various contaminants, all of which directly impact the brush wear rate and the motor's expected lifespan. Therefore, the design must focus on resilience and fault tolerance, treating the carbon brush as a precisely engineered critical component, not merely a simple consumable.

Addressing Thermal Stress and Thermal Cycling:

Automotive engine cooling fans and air conditioner condenser fans are continuously subjected to extreme hot and cold cycles. The motor temperature can rapidly climb from ambient to over 100°C within minutes. This cycling causes thermal expansion and contraction in the commutator and the brush body.

Thermal Expansion Compatibility and Structural Stability: Cooling fan and condenser fan motors experience rapid and significant temperature changes during startup and shutdown. In this harsh thermal cycling environment, the carbon brush material's Coefficient of Thermal Expansion must be closely matched with the CTE of the copper commutator and the brass/steel brush holder. A significant mismatch can lead to uncontrolled changes in the brush holder clearance, which might cause the brush to seize, preventing smooth sliding and resulting in instantaneous contact loss and arcing; in severe cases, it can cause the carbon brush to crack or shatter. Therefore, automotive fan carbon brush manufacturers ensure outstanding dimensional stability and mechanical integrity throughout the operating temperature range by precisely selecting and adjusting the grade and formula of the graphite material.

Efficient Heat Dissipation and Temperature Control: Due to their proximity to the engine or high-pressure refrigerant coils, motor components must effectively dissipate heat. The carbon brush structure itself, particularly for metal-graphite grades, provides an excellent thermal conduction path, helping to draw heat away from the critical contact surface. Poor thermal management can lead to increased brush resistance, accelerated wear, and severely compromise the long-term durability required for the fan or condenser system.

Designed for Mechanical Vibration and Shock:

Vibration is an unavoidable factor in all vehicle systems. Engine vibration, road shocks, and the inherent rotational imbalance of the fan blades are directly transmitted to the motor's carbon brush mechanism.

Brush Stability and Bounce Suppression: Extreme vibration or shocks can cause the carbon brush to momentarily lift or "bounce" off the commutator surface. This phenomenon leads to severe arcing, rapidly eroding both the brush and the commutator, ultimately causing catastrophic motor failure. Therefore, our design engineers precisely optimize the dynamic performance of the spring and the mass of the carbon brush to minimize the system's resonant frequency, ensuring stable and continuous electrical contact even under dynamic loads.

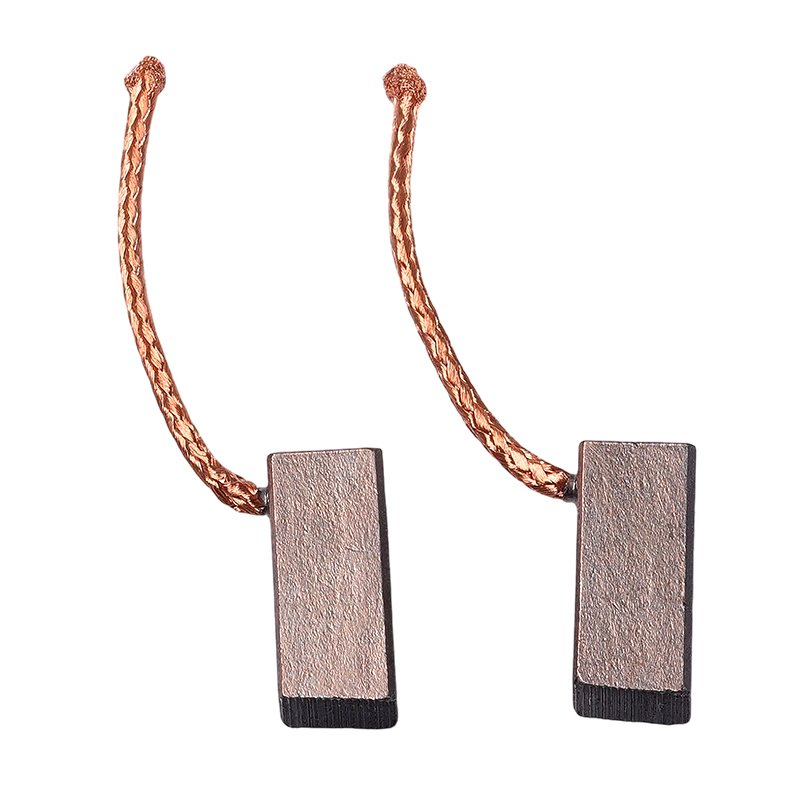

Pigtail and Terminal Durability: As the flexible copper braid that conducts current, the pigtail must withstand continuous bending during operation without fracturing or suffering metal fatigue at the connection points. We employ reliable, low-impedance soldering or brazing methods to secure the pigtail, guaranteeing the mechanical strength and electrical continuity of this connection point, providing the reliable conductivity consistently needed for the automotive condenser carbon brush.

Resistance to Environmental Contaminants:

Automotive cooling system motors are not always perfectly sealed and are inevitably exposed to dust, moisture, and even oil and chemical vapors from the engine bay.

Material Chemical Inertness and Protection: Carbon brush materials must maintain high chemical inertness against common automotive fluids, such as coolant vapor, oil, or cleaning agents. Certain chemical residues can contaminate the critical protective film on the commutator surface, leading to a sharp increase in friction, significant noise generation, and accelerated brush wear. Our material formulation effectively resists this chemical erosion.

Self-Cleaning Characteristics and Contact Film Maintenance: High-performance graphite materials possess a degree of self-cleaning action. This unique material structure helps to absorb or remove minor contaminants from the contact surface, which is crucial for maintaining the integrity of the protective film on the commutator, thereby ensuring the reliable motor performance required by the fan or condenser system.

Product Excellence: Engineering Advantages of Condenser Fan Motor Carbon Brushes

Our automotive condenser fan motor carbon brushes are specifically designed and engineered to deliver three core advantages: stable conductivity, reliable motor performance, and long-term durability under continuous operation. This is achieved through our proprietary material science and precision assembly technology.

Stable Conductivity and High Efficiency:

Achieving stable conductivity is fundamental to maximizing motor efficiency and minimizing electromagnetic interference.

Proprietary Material Blend and Low Resistivity: We utilize an optimized blend of carbon and high-purity copper powder. This metal-graphite composite is chosen for its extremely low electrical resistivity, which ensures high conductivity and minimizes energy loss and heat generation.

Low Contact Voltage Drop and Oxide Film: The precisely formulated material facilitates the rapid formation of a stable, thin, and uniform protective film (oxide film) on the commutator surface. This film is crucial for maintaining a consistent and predictable low contact voltage drop, directly enhancing motor efficiency and effectively lowering operating temperature.

Secure Pigtail Bonding and Reliability: The copper pigtail is connected to the carbon brush body using specialized brazing or welding techniques, creating a connection point with ultra-low resistance. This connection remains stable under both thermal and mechanical stress, guaranteeing reliable conductivity throughout the entire service life of the carbon brush.

Reliable Motor Performance:

Reliable motor performance hinges on perfect commutation—the process of reversing the current in the rotor windings. Any instability can lead to sparking and rapid component damage.

Optimized Commutation Profile and Current Density: Our carbon brush material is manufactured with specific porosity and density to ensure uniform current density distribution across the entire contact surface, even during startup, speed changes, or high-load operation. This uniformity eliminates localized hotspots, significantly reducing the potential for sparking.

Minimized Noise and EMI Suppression: By ensuring a stable, arc-free commutation process, our carbon brushes fundamentally reduce acoustic noise and electromagnetic interference, which is vital for the increasingly sensitive electronic systems in modern vehicles that demand electromagnetic compatibility.

Dynamic Stability Spring System: Each carbon brush is paired with a precisely calibrated constant-force spring. This spring consistently maintains the optimal contact pressure against the commutator, independent of vibration or temperature changes, ensuring stable operation and effectively preventing brush bounce during high-speed rotation.

Long-Term Durability and Service Life:

Our carbon brushes are meticulously designed to deliver long service life and long-term durability, consistently meeting or exceeding OEM standards for the entire lifecycle of the fan motor assembly.

High Wear Resistance Material and Low Loss: The crystalline structure of the graphite is specially engineered for high mechanical strength and low abrasiveness, resisting frictional effects and preventing material degradation over millions of contact cycles.

Moisture and Corrosion Resistance: Through advanced impregnation and surface treatments, the carbon brush material effectively resists moisture absorption and maintains chemical stability against automotive coolants, salt spray, and atmospheric contaminants. This is critical for maintaining functionality in the harsh engine bay environment.

Self-Lubricating Properties and Smooth Operation: The inherent lubricity of graphite ensures an extremely low coefficient of friction, minimizing wear on the commutator while allowing the brush to slide smoothly within the brush holder, preventing sticking and ensuring reliable operation until it reaches its intended wear limit.

Modern Manufacturing and Quality Protocols

The demanding operating environment mandates that every automotive fan/condenser carbon brush assembly adheres strictly to extremely high manufacturing precision and quality assurance standards. For suppliers in this field, maintaining consistency across millions of units is a key measure of capability.

Precision Manufacturing Process:

Carbon brush production involves several precise steps, each of which is critical to the final product's performance characteristics.

Precise Control of Mixing and Compounding: The exact ratio of carbon, graphite, metal powders, and resins is controlled to within minimal tolerance ranges. This compounding process determines the final electrical, mechanical, and thermal properties of the carbon brush material.

Optimization of Forming and Sintering Processes: The raw material mixture is pressed into shape under high pressure and then enters the sintering or high-temperature heat treatment phase. The precise control of temperature and atmospheric conditions during this phase determines the final hardness, density, and crystalline structure of the graphite, directly impacting the brush's wear resistance and its ability to maintain long-term durability.

Precision Finishing and Dimensional Verification: After high-temperature processing, the carbon brush blocks undergo precision machining, grinding, and polishing. We use advanced optical and contact measurement equipment to verify dimensional accuracy, ensuring the brush fits perfectly within the holder, a core requirement for any automotive condenser carbon brush manufacturer.

Integrated Quality Assurance and Supply Chain Management:

In the automotive supply chain, quality encompasses not just the final product but the entire manufacturing and management process. This integrated approach ensures every component meets rigorous performance and process standards.

Rigorous Material Property Testing: Every batch of carbon material must be tested for core attributes such as hardness, bulk density, resistivity, and flexural strength. Only materials that fall within the stipulated strict tolerance ranges are permitted for the manufacture of automotive fan carbon brushes.

Full-Process Quality Control System: We implement a comprehensive quality management system across the entire production lifecycle, from raw material procurement to finished product assembly. This dedication to consistency and process control is a fundamental practice of leading suppliers, ensuring the reliability of products from a China automotive fan/condenser carbon brush manufacturer that partners with top global motor brands.

Operational Excellence and Strategic Partnership: As a leader in this field and a professional automotive fan/condenser carbon brush supplier, we establish high industry standards by employing advanced ERP systems. This ensures the leanness of processes, the efficiency of material tracking, and the reliability of component supply. It is this systematic approach that has led to continuous "Excellent Supplier" recognition from major motor corporations.

Through strict adherence to comprehensive quality control protocols and a commitment to independent innovation, our manufacturers continuously improve carbon brush technology. This ongoing practice ensures that the automotive fan/condenser carbon brushes supplied to the global market meet the growing demands for efficiency, quiet operation, and longevity in modern vehicle systems.

English

English 中文简体

中文简体