How do specialized materials guarantee wiper motor reliability?

The windshield wiper system is a crucial safety component in any vehicle, demanding absolute reliability across a wide range of operating conditions, from high-speed continuous wiping in heavy rain to intermittent use in light drizzle. The demands placed on the DC motor at the heart of this system are rigorous, particularly concerning electromagnetic interference, noise suppression, and long service life. The Automotive Windshield Wiper Motor Carbon Brushes are central to meeting these requirements, serving as the electrical and physical interface that defines the motor's performance characteristics. For companies designated as Wholesale Automotive Windshield Wiper Motor Carbon Brushes Manufacturers, achieving this balance requires sophisticated material science and ultra-precise manufacturing techniques.

Material Formulation for Durability and Acoustic Performance:

Automotive applications demand a carbon brush material that can handle highly dynamic loads and variable duty cycles while remaining exceptionally quiet and highly durable throughout the vehicle’s lifespan.

Low-Friction Carbon-Graphite Grades: For most standard passenger vehicle wiper motors, specialized carbon-graphite materials are favored. These compositions are engineered for low friction to minimize mechanical drag on the commutator, which is essential for reducing audible noise. The material is formulated to create an extremely stable, thin protective film or patina on the copper commutator surface. This film acts as a boundary lubricant and the primary electrical contact layer, preventing excessive wear on both the brush and the commutator. The goal is to achieve minimal sparking and consistent current transfer, ensuring smooth operation across all wiper speeds.

Metal-Graphite for High-Torque/Heavy-Duty Motors: Larger vehicles, such as trucks, buses, or heavy-duty utility vehicles, require wiper systems with significantly higher torque capacity to handle larger blade areas and heavier loads, often including snow or ice. For these applications, the Automotive Windshield Wiper Motor Carbon Brushes may incorporate small amounts of fine metallic powder, typically copper or silver, into the graphite matrix. The metal content substantially increases the electrical conductivity and improves the brush's ability to carry the higher current demands of a high-torque motor. This is achieved while carefully limiting the metal concentration to preserve the necessary self-lubricating qualities of the graphite, ensuring long-lasting durability without accelerating commutator wear.

Resin Binders and Additives for Environmental Stability: Automotive motors must function reliably from sub-zero temperatures to extreme heat. The materials used in the carbon brush must maintain their structural integrity and electrical properties across this entire thermal spectrum. Specialized high-temperature resin binders are used to stabilize the carbon block, preventing structural degradation, softening, or changes in mechanical resilience. Furthermore, trace additives are carefully incorporated into the matrix to control the density and hardness, ensuring the brush maintains a consistent wear rate and reliable motor performance regardless of ambient conditions.

Acoustic Optimization through Density Control: A key differentiator for Automotive Windshield Wiper Motor Carbon Brushes Manufacturers is the control of acoustic emissions. The rubbing of the brush against the commutator generates noise. Manufacturers achieve quiet operation by meticulously controlling the material porosity and density. A properly tuned material absorbs some of the frictional vibrations, contributing to silent operation, which is a significant factor in vehicle cabin comfort. The engineering process aims for a vibration-dampening brush structure that ensures the wiper motor is practically inaudible during normal use.

Precision Design and Mechanical Integration:

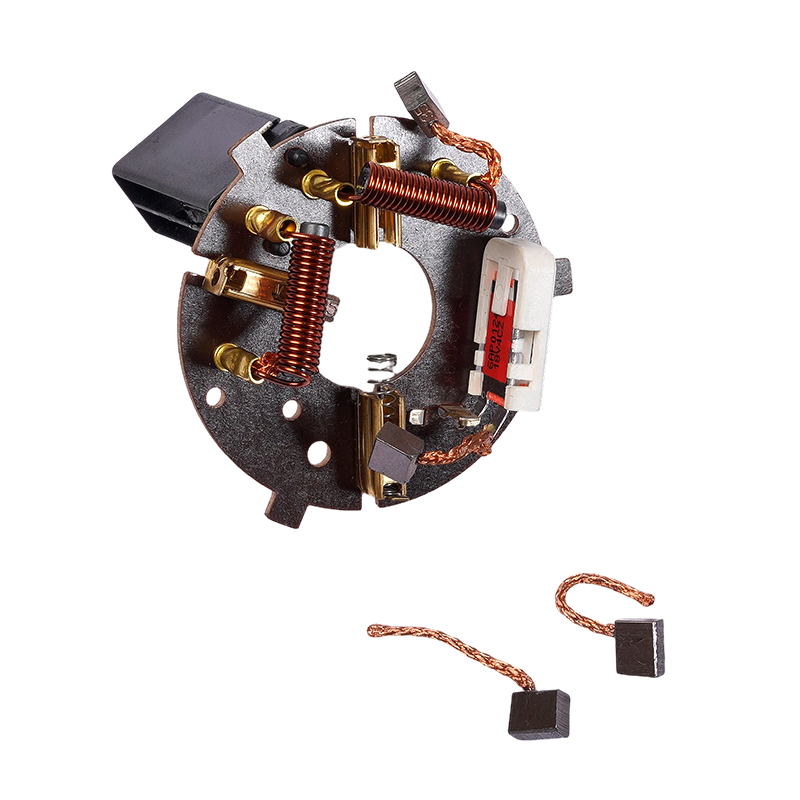

The physical design of the carbon brush and its assembly components are engineered to guarantee constant, uniform contact pressure and perfect fitment.

Dimensional Consistency and Tolerances: Due to the precision required by the compact wiper motor assembly, the carbon block's dimensions are subject to exceptionally tight tolerances. The brush must slide freely within the brush holder without binding, which would interrupt the electrical connection. Advanced manufacturing techniques, including high-precision grinding and non-contact metrology, ensure that the parallelism and squareness of the brush faces are perfect. This dimensional accuracy is non-negotiable for guaranteeing smooth operation and a consistent wear profile over the product's extended lifetime.

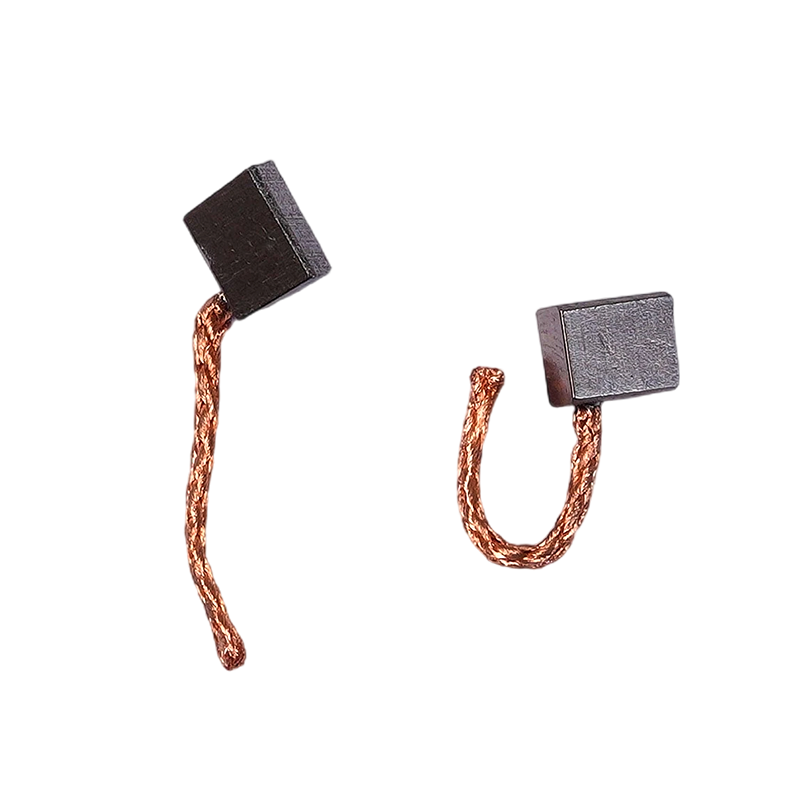

Pigtail and Connection Integrity: The copper shunt wire, or pigtail, is critical for transferring current from the holder to the carbon block. It must be highly flexible to accommodate the brush's movement as it wears down. The attachment point to the carbon block is a low-resistance connection created through high-energy bonding processes, such as ultrasonic welding or precise brazing. This robust connection ensures reliable conductivity and exceptional mechanical durability, resisting the continuous vibration and thermal cycling inherent to automotive operation.

Optimized Spring Systems for Contact Stability: The spring assembly provides the mechanical force to keep the brush firmly against the commutator. This spring must be engineered from high-fatigue alloys to maintain consistent pressure throughout the entire wear life of the carbon brush. Maintaining uniform pressure prevents brush bounce and minimizing arcing, which are common causes of premature commutator damage and electromagnetic interference EMI. Consistent, calibrated spring force is fundamental to achieving long-lasting durability and minimizing maintenance.

What quality standards ensure long-term wiper brush function?

The automotive industry operates under some of the world's most demanding quality and safety standards. Components like Automotive Windshield Wiper Motor Carbon Brushes are classified as safety-critical parts, requiring manufacturers to implement systems that ensure zero defects and lifetime reliability under all operating scenarios.

Quality Management and Process Control:

Reliable supply to global automotive Original Equipment Manufacturers OEMs requires a structured, data-driven approach to production quality that begins with raw materials and extends through final shipment.

Full-Process Quality Control: Manufacturers must adhere to rigorous quality management systems to govern every stage of production. This includes stringent procedures for raw material validation, controlling the particle size and purity of carbon powders, and maintaining precise control over the mixing, pressing, and baking thermal cycles. Following standards like ISO 9001 for full-process quality control establishes the fundamental framework for consistent and repeatable product outcomes. This foundational quality adherence is crucial for a reliable Automotive Windshield Wiper Motor Carbon Brushes Manufacturers operating on a large scale.

Advanced Automotive Quality Standards: To secure and maintain partnerships in the automotive sector, component suppliers must demonstrate a commitment to the most stringent quality protocols. The possession of the IATF 16949 certification, which is recognized globally for automotive component supply chain management, signifies an elevated quality benchmark. This dedication to elevated standards is paramount for parts like windshield wiper brushes, where failure directly impacts vehicle safety.

Efficiency through System Integration: High-volume manufacturers must rely on sophisticated operational tools to ensure efficiency and traceability. The adoption of an advanced ERP system in production provides crucial real-time management of batch consistency, inventory, and end-to-end component traceability. This systemic control is essential for producing millions of highly uniform and reliable units, ensuring the competitiveness required by Wholesale Automotive Windshield Wiper Motor Carbon Brushes Manufacturers in the global market.

Manufacturer's Commitment to Quality:

Jiangsu Hailing Carbon Products Co., Ltd. is recognized in the industry as a dedicated China Automotive Windshield Wiper Motor Carbon Brushes Manufacturers and Automotive Windshield Wiper Motor Carbon Brushes Suppliers. The company adheres to the principle of "Integrity in Operation, Quality First" and strategically follows "Brand Building, Independent Innovation." This strategic guidance drives continuous refinement in material science and manufacturing processes. By consistently investing in new equipment and independent research, the manufacturer ensures its Automotive Windshield Wiper Motor Carbon Brushes maintain top industry performance. The manufacturer's dedication to quality is recognized through its partnerships with top domestic and international motor brands, frequently resulting in "Excellent Supplier" awards. This focus on verifiable quality and operational excellence ensures the supply chain is robust and reliable, providing the essential foundation for producing safety-critical automotive components. The manufacturer also holds High-Tech Enterprise qualification and adheres to various certifications, including ISO 14001 for environmental management and ISO 45001 for occupational health and safety, further demonstrating a comprehensive commitment to responsible and high-standard production of Automotive Windshield Wiper Motor Carbon Brushes.

Electrical Performance and Environmental Testing:

Validation of Automotive Windshield Wiper Motor Carbon Brushes extends beyond physical dimensions to include rigorous testing of electrical and environmental resilience.

EMI and Noise Suppression Testing: A primary function of the carbon brush is to minimize electrical noise generated during commutation, which can interfere with the vehicle's sensitive electronic systems. Brushes are tested on specialized motor rigs to measure electromagnetic interference EMI and radio frequency interference RFI levels across the full operating speed range. The material formulation is fine-tuned to ensure exceptional commutation stability, thereby suppressing arcing and electrical noise, which is critical for reliable motor performance in modern vehicles.

Current Density and Thermal Stability Testing: Automotive Windshield Wiper Motor Carbon Brushes must handle variable current loads without suffering thermal degradation. Testing involves subjecting the brush to maximum rated current for extended periods while monitoring temperature and contact voltage stability. This confirms that the brush assembly can dissipate heat efficiently and that the pigtail connection remains stable, ensuring reliable conductivity and preventing premature failure due to excessive heat.

Durability and Climate Cycling: The automotive environment requires components to withstand extreme climatic variations. Brushes are subjected to climate chambers simulating rapid changes between freezing and high-heat conditions, often with controlled humidity. This testing verifies that the material maintains its structural integrity, coefficient of friction, and electrical properties under all potential operating climates, contributing significantly to the component's long-lasting durability.

Application-Specific Carbon Brush Characteristics

This reference table outlines the specific material and performance attributes engineered into Automotive Windshield Wiper Motor Carbon Brushes for various motor demands.

|

Wiper Motor Application

|

Primary Material Grade Type

|

Electrical/Noise Focus

|

Durability and Performance Attribute

|

|

Standard Passenger Car Front Wiper

|

Low-Friction Carbon-Graphite

|

High Acoustic Damping and Low EMI Generation

|

Engineered for Extended Service Life and Smooth Operation in intermittent use

|

|

Heavy-Duty Truck/Bus Wiper System

|

Copper-Graphite Composite

|

High Current Capacity and Thermal Management

|

Optimized for High Torque Loads, ensuring Reliable Conductivity and stability

|

|

Intermittent/Rain-Sensing Systems

|

High-Purity Electrographite

|

Exceptional Film Stability in Variable Duty Cycles

|

Features a Consistent Wear Rate, promoting Long-lasting Durability and low maintenance

|

|

Rear Wiper Motor Assembly

|

Specialized Resin-Treated Graphite

|

Consistent Contact Pressure for Low-Speed Operation

|

Designed for Compact Motors, delivering consistent reliable motor performance

|

The manufacturer maintains a forward-looking strategy focused on independent innovation and the rigorous practice of lean management throughout its production processes. This approach is essential for rapidly adapting to the evolving motor technology and escalating quality requirements of the global automotive sector. By prioritizing process control and material refinement, the manufacturer strengthens its foundational competitive position in the Automotive Windshield Wiper Motor Carbon Brushes market, ensuring the supply of components that meet the high standards for vehicle safety, efficiency, and operational longevity.

English

English 中文简体

中文简体