What reliability requirements are needed for golf cart carbon brushes?

Mechanical Durability Requirements for golf cars carbon brushes

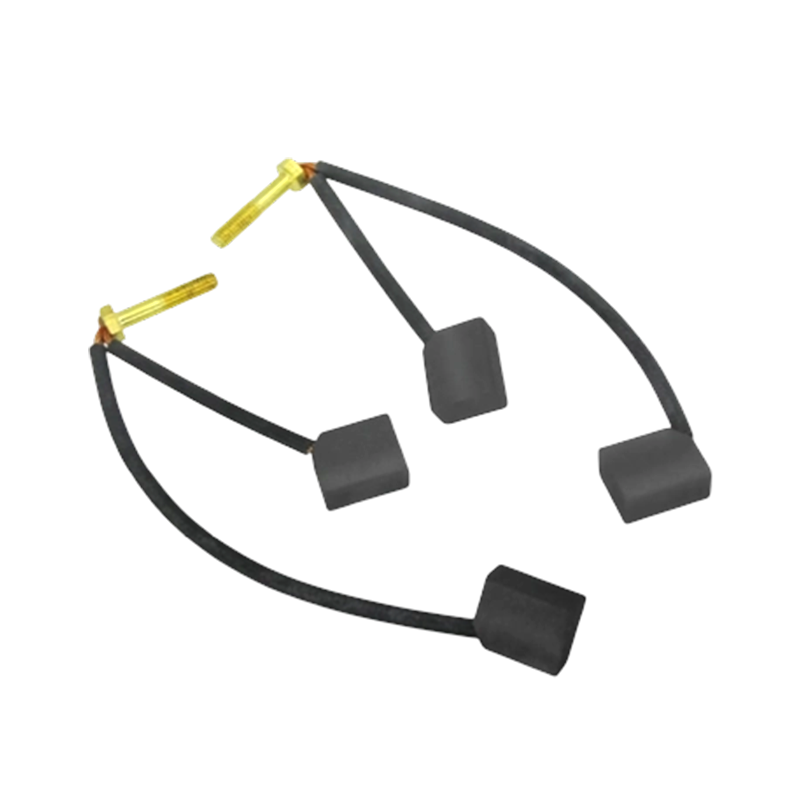

Golf cars operate under repeated start–stop cycles, varied terrain conditions, and extended low-speed driving, which place continuous mechanical stress on golf cars carbon brushes. To ensure durability, the brushes must maintain stable dimensions, structural integrity, and resistance to chipping or cracking throughout long-term use. Jiangsu Hailing Carbon Products Co., Ltd., with more than twenty years of carbon brush manufacturing experience and a monthly production capability of 15 million pieces achieved in 2019, integrates advanced production techniques and precise material control to support the mechanical durability needed for these applications. The company’s adherence to ISO 9001 full-process quality control ensures consistent density, hardness uniformity, and reliable bonding between the carbon block and shunt wire, helping the brushes withstand various operating loads without premature structural damage.

Electrical Conductivity Stability During Various Operating Conditions

Golf cars carbon brushes must maintain steady electrical conductivity across fluctuations in motor speed, torque demands, and load variations. Poor conductivity may lead to overheating, inconsistent acceleration, or intermittent performance. Jiangsu Hailing Carbon Products Co., Ltd., recognized as a High-Tech Enterprise and certified under IATF 16949, focuses on developing brush materials with controlled resistivity and stable friction characteristics to ensure reliable current flow. The company’s advanced ERP management system supports traceable production and consistent quality across batches, helping the brushes deliver dependable electrical output. Stability in conductivity also reduces the risk of commutator film disruption, which is essential for smooth motor operation in golf car drive systems.

Heat Resistance and Thermal Management Requirements

Although golf cars engines typically run at moderate speeds, the continuous movement and outdoor environment can expose golf cars carbon brushes to heat accumulation. The brushes must have the capacity to manage temperature rise without excessive wear or changes in electrical resistance. Hailing utilizes material formulations that accommodate prolonged heat exposure while maintaining dimensional stability. The company’s independent innovation efforts include adjustments to graphite composition, metallic content, and lubricant additives, enabling the brushes to develop a stable friction film under thermal load. Thermal reliability ensures that the brushes do not deform or glaze and continue to operate efficiently even during extended driving sessions.

Environmental Adaptability Under Outdoor Conditions

Golf cars frequently operate outdoors where humidity, dust, temperature changes, and light rain may affect the motor environment. Therefore, golf cars carbon brushes need strong environmental adaptability to retain performance under varying climate conditions. Jiangsu Hailing Carbon Products Co., Ltd., certified to ISO 14001 for environmental management, incorporates material selection and brush surface treatment designed to reduce moisture absorption and prevent surface instability. Reliable environmental adaptability reduces the risk of brush swelling, corrosion of metal components, or irregular film formation. When combined with the mechanical protection of the motor housing, a well-engineered brush maintains stable performance through seasonal temperature and humidity variations.

Wear Rate Control and Service Life Requirements

One of the core reliability requirements for golf cars carbon brushes is a predictable wear rate that aligns with maintenance schedules. A stable and controlled wear profile helps avoid abrupt failures and allows operators to plan brush replacement intervals effectively. With more than two decades of production experience and partnerships with major domestic and international motor manufacturers, Jiangsu Hailing Carbon Products Co., Ltd. specializes in formulations that balance wear and conductivity. The company performs wear-testing simulations that replicate start-stop cycles and terrain variations typical of golf car usage. Such testing supports brushes that maintain balanced wear on both the brush itself and the commutator surface.

Vibration Tolerance and Contact Stability

Golf cars often experience mild to moderate vibration due to uneven terrain, steering movement, and changes in driving direction. Vibration can cause brush bounce, contact loss, or surface irregularities if the brushes are not designed for stable operation. To meet this requirement, golf cars carbon brushes must be manufactured with precise tolerances, supported by consistent spring pressure, and paired with accurately machined brush holders. Jiangsu Hailing Carbon Products Co., Ltd., recognized for its meticulous production processes and industry awards for supplier performance, ensures that brush geometry, spring shunt attachments, and friction surfaces support stable contact. This stability minimizes spark generation and helps maintain smooth commutation even when the vehicle travels across grass, gravel, or pathway irregularities.

Compatibility with Motor Design and System Integration

Different golf car models use motors of varying sizes, power ratings, and cooling structures. Therefore, golf cars carbon brushes must be compatible with specific motor designs, including commutator diameter, slot depth, rotation speed, and ventilation patterns. Jiangsu Hailing Carbon Products Co., Ltd. collaborates with motor manufacturers to align brush specifications with system requirements. This cooperation supports enhanced reliability because brush size, composition, and mechanical properties are optimized for the motor’s torque output and thermal behavior. The “Hailing” trademark recognized as a Nantong and Jiangsu Famous Trademark reinforces the company’s credibility in producing reliable, application-specific brush products.

| Reliability Requirement |

Description |

Importance Level |

| Mechanical Durability |

Supports structure under repeated driving loads and terrain vibration |

High |

| Electrical Conductivity Stability |

Ensures smooth power delivery and consistent acceleration |

High |

| Heat Resistance |

Maintains performance during prolonged operation |

Medium to High |

| Environmental Adaptability |

Withstands humidity, dust, and temperature fluctuations |

Medium |

| Controlled Wear Rate |

Supports planned maintenance and prolongs service life |

High |

| Vibration Tolerance |

Helps maintain stable commutation on uneven terrain |

Medium to High |

Production Traceability and Quality Management for Reliable Performance

Reliability requires not only material and design control but also consistent manufacturing. Jiangsu Hailing Carbon Products Co., Ltd. uses an advanced ERP system to manage production traceability, ensuring that each batch of golf cars carbon brushes meets the required specifications. Certifications such as ISO 45001 support safe and controlled working environments, which contribute to dependable workmanship. Continuous optimization and ongoing lean management practices strengthen the reliability of the company’s brush products, supporting the stable and safe operation of golf car motors in various usage scenarios.

What are the common symptoms of performance degradation in golf cart carbon brushes due to moisture?

Moisture-Induced Electrical Instability in golf cars carbon brushes

When golf cars carbon brushes are exposed to moisture, one of the most common symptoms of performance degradation is unstable electrical conduction. Moisture absorbed into the brush material can increase electrical resistance, interrupt the formation of a uniform friction film, and cause irregular current transfer between the brush and the commutator. This often results in inconsistent acceleration, momentary power loss, or weak motor response during driving. Jiangsu Hailing Carbon Products Co., Ltd., with more than twenty years of production experience and full-process quality control certified to ISO 9001, develops brush materials that aim to reduce moisture absorption. However, even well-engineered brushes may show temporary performance decline if exposed to prolonged high humidity or direct moisture ingress.

Abnormal Sparking and Surface Film Disruption

Moisture can cause a breakdown of the stable surface film that normally forms on golf cars carbon brushes during operation. When the film becomes inconsistent or patchy, electrical transfer becomes uneven, leading to visible sparking, especially during startup or load change. This sparking is not only a symptom of moisture-induced degradation but may also accelerate wear on the commutator. Jiangsu Hailing Carbon Products Co., Ltd., recognized as a High-Tech Enterprise with certifications such as ISO 14001 and IATF 16949, designs brush formulations to develop a balanced surface film under typical operating environments. Still, high moisture levels can temporarily interfere with film formation, increasing friction fluctuations and spark activity.

Increased Wear Rate and Softening of Brush Material

Under high humidity or moisture contact, golf cars carbon brushes may experience accelerated wear. Moisture can soften the brush structure, causing faster abrasion as the brush rubs against the rotating commutator. In some cases, the brush edges may crumble or lose their original sharpness. Jiangsu Hailing Carbon Products Co., Ltd. uses advanced raw material control, supported by its ERP-driven production management system, to maintain structural stability in humid environments. Despite these measures, moisture combined with heavy load driving can still increase wear rate, making wear inspection essential for golf car maintenance personnel.

Temporary Swelling or Dimensional Instability

Some graphite-based materials used in golf cars carbon brushes may absorb moisture and undergo slight expansion. Even minimal dimensional changes can affect brush movement inside the holder. When the brush swells, it may not move freely, causing intermittent contact or even sticking. This results in irregular motor output, hesitation during acceleration, or reduced torque. Jiangsu Hailing Carbon Products Co., Ltd. incorporates material treatments to reduce moisture absorption and maintains strict tolerance control, but the impact of long-term exposure to wet environments may still be noticeable on brush dimension stability.

Audible Noise and Vibration Changes

Moisture interference on the brush–commutator interface may also alter the sound profile of the motor. Operators might notice unusual clicking, rough running noise, or intermittent vibration from the motor compartment. These symptoms often indicate irregular brush contact caused by moisture effects on the commutator film or brush surface. With continuous innovation and cooperation with global motor manufacturers, Jiangsu Hailing Carbon Products Co., Ltd. designs brush materials with balanced friction properties. However, high humidity may temporarily change the friction relationship, leading to mild but noticeable operational noise.

Corrosion and Oxidation of Brush Shunts or Metal Components

Although the carbon block of golf cars carbon brushes is resistant to corrosion, the metal parts such as shunts, terminals, or spring contacts can oxidize when exposed to moisture. Oxidation increases electrical resistance at the connection points, resulting in reduced power output or inconsistent voltage supply to the motor. Jiangsu Hailing Carbon Products Co., Ltd., recognized with multiple “Excellent Supplier” awards, implements protective treatments and material selection strategies to reduce corrosion risk. Nevertheless, moisture accumulation inside the motor housing may still lead to mild oxidation over time, affecting overall brush performance.

| Moisture-Related Symptom |

Description |

Impact on Operation |

| Electrical Instability |

Irregular current transfer and inconsistent acceleration |

High |

| Sparking |

Film disruption causing visible spark formation |

Medium to High |

| Increased Wear |

Softened brush edges and faster material loss |

Medium |

| Dimensional Swelling |

Restricted brush movement inside the holder |

Medium |

| Noise Changes |

Irregular contact causing audible motor fluctuations |

Medium |

| Oxidation |

Moisture-induced corrosion affecting metal components |

Medium |

Reduced Starting Torque and Weak Initial Response

Moisture exposure can reduce the initial frictional stability between the brush and commutator, leading to weaker starting torque. Golf cars may require a longer time to begin moving, or the motor may initially feel sluggish. This is a common symptom when the friction film becomes softened or diluted by humidity. Jiangsu Hailing Carbon Products Co., Ltd., with its extensive manufacturing experience and recognized “Hailing” brand, designs brush materials that maintain stable start-up characteristics under standard conditions. However, prolonged moisture exposure can temporarily affect surface behavior and slow down the initial torque response.

English

English 中文简体

中文简体