Does the uniformity of wear on household appliance carbon brushes affect motor performance and efficiency?

Impact of Wear Uniformity on the Conductive Stability of Household Appliance Carbon Brushes

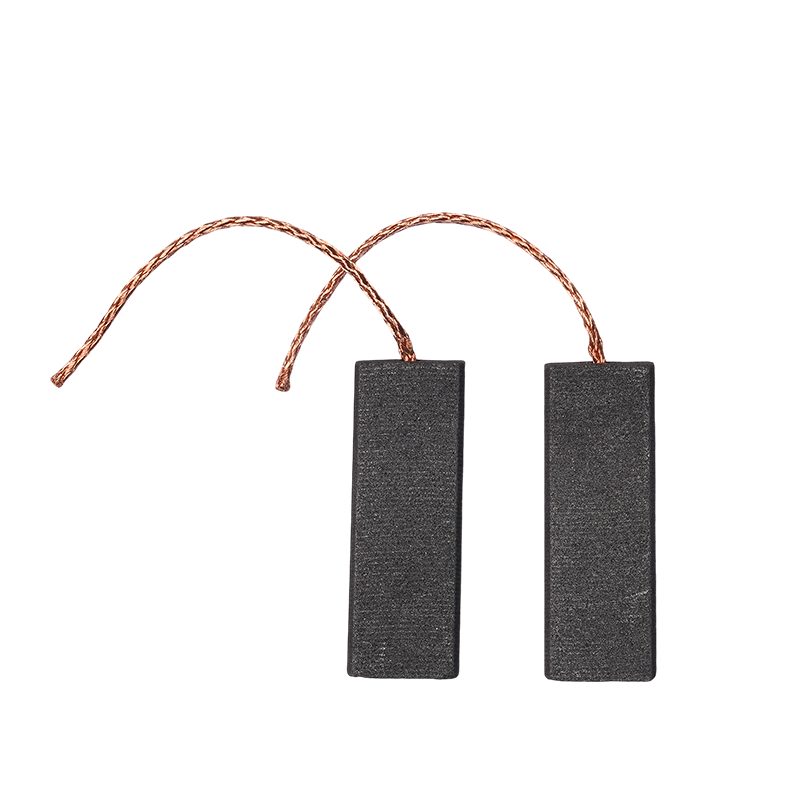

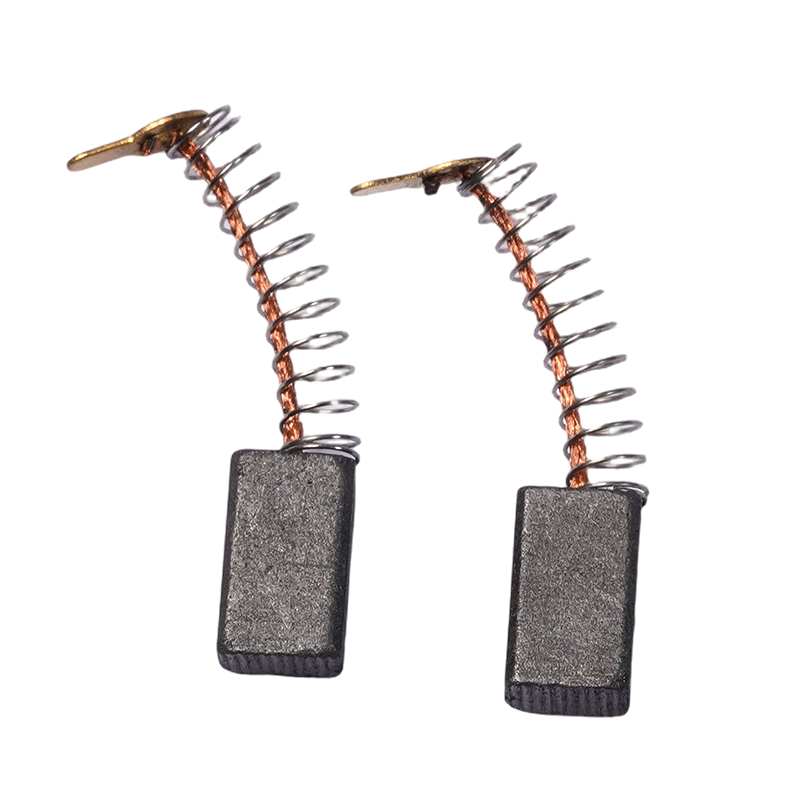

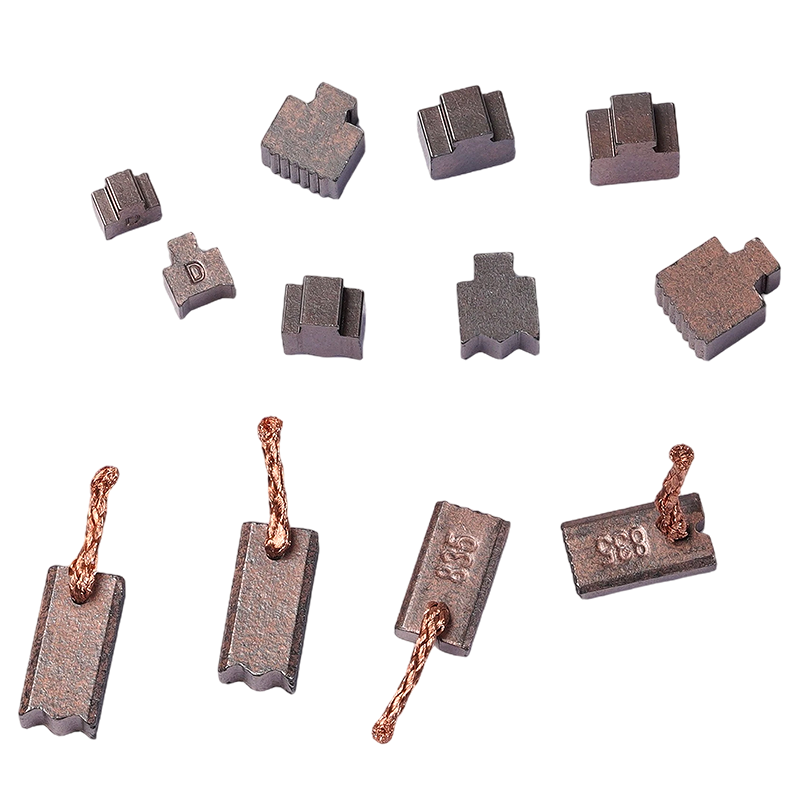

In household appliances that use universal motors or brushed DC motors, the contact between the carbon brush and the commutator determines the continuity of power transmission. When the wear pattern on household appliance carbon brushes is even, the conductive surface remains stable, helping maintain consistent current flow during operation. Uneven wear, however, may cause intermittent contact, minor arcing, or fluctuations in electrical resistance, affecting both performance and operational smoothness. As a household appliance carbon brushes factory with strong production control, Jiangsu Hailing Carbon Products Co., Ltd. applies ISO 9001 full-process quality management to ensure that wear behavior is predictable and controlled. Through careful material formulation and precision machining, the brushes are designed to form a smooth and continuous contact arc as they wear down, which contributes to stable motor performance in daily-use appliances such as vacuum cleaners, mixers, washing machines, and hair dryers.

Relationship Between Brush Wear and Motor Efficiency

Motor efficiency depends in part on the quality of brush-to-commutator contact. When wear is uniform, friction remains consistent, which helps the motor maintain a steady torque output. Irregular wear can increase friction or produce uneven pressure distribution, causing additional energy consumption. Over time, the motor may require more power to maintain the same performance level. Jiangsu Hailing’s advanced ERP system helps coordinate production parameters such as density control, surface finishing, and material hardness. These parameters influence the stability of brush wear across different household appliance models. A brush that wears in a controlled pattern helps minimize unnecessary electrical loss, reduce temperature rise, and support steady motor efficiency throughout the appliance’s service life.

How Brush Design and Material Influence Wear Uniformity

The formulation of graphite, resin binders, and metal powders plays a key role in ensuring uniform wear. Hailing has continuously invested in new equipment and independent innovation to optimize these material blends. The objective is to achieve balanced lubricity, hardness, and electrical conductivity that adapt to different rotation speeds and commutator materials found in household appliances. Uniform wear also depends on the brush’s structural tolerances. The company’s machining processes are designed to maintain stable dimensions and consistent surface smoothness. These factors help the carbon brush fit properly in the brush holder, ensuring that spring pressure is evenly distributed. When combined, these characteristics support a controlled wear pattern that helps protect both the brush and the motor.

Effects of Uneven Wear on Motor Noise and Stability

Uneven wear can lead to vibration due to irregular contact with the commutator. This vibration may become audible as clicking, buzzing, or intermittent noise during appliance operation. In extreme cases, it may also contribute to commutator damage, leading to accelerated wear for both components. Because Jiangsu Hailing Carbon Products Co., Ltd. has long partnered with leading motor manufacturers, its household appliance carbon brushes meet various operational conditions that demand controlled wear characteristics. This partnership ensures that brushes are tested in different appliance models to verify their performance in real-world scenarios. The outcome is reduced noise, smoother rotation, and stable torque output.

Influence of Wear Uniformity on Service Life Prediction

Predicting service life is important for household appliance manufacturers and end users. When wear patterns are regular and consistent, estimating remaining brush life becomes easier. This improves maintenance planning and reduces sudden appliance breakdowns. In contrast, unexpected uneven wear may cause irregular performance or early failure. Hailing’s production system verifies material uniformity and structural precision through strict internal inspections. As a household appliance carbon brushes factory certified with ISO 14001, ISO 45001, and IATF 16949, it ensures that each brush batch follows the required industrial standards. This allows appliance manufacturers to rely on predictable performance data and build products with more stable long-term reliability.

Factors Influencing Wear Uniformity of Household Appliance Carbon Brushes

| Factor |

Description |

Impact on Wear |

| Material Composition |

Graphite and resin blend tailored for conductivity and lubrication |

Affects friction stability and wear balance |

| Surface Finish |

Polished surface to ensure smooth initial contact |

Supports even wear during early operation |

| Brush Holder Fit |

Dimensions produced with precision machining |

Reduces tilt and uneven pressure distribution |

| Spring Pressure |

Maintains steady brush-to-commutator contact |

Prevents irregular friction patterns |

| Motor Speed |

Speed varies across household appliance models |

Affects heating, friction, and wear pattern |

Importance of Quality Control in Ensuring Wear Uniformity

Quality control is essential for ensuring predictable wear behavior. Hailing’s ISO-based quality system allows each production stage—from raw material selection to finished brush testing—to be documented, measured, and continuously improved. This structured system reduces variations between batches and helps maintain long-term uniformity. The company’s recognition as a “Nantong Famous Trademark” and “Jiangsu Famous Trademark” reflects its reputation for consistent manufacturing performance. It also demonstrates the reliability that appliance manufacturers expect when sourcing household appliance carbon brushes from an experienced supplier.

Why Wear Uniformity Matters for Appliance Manufacturers

Manufacturers rely on predictable brush performance to design motors that are durable and energy-efficient. When brushes from a stable source such as Jiangsu Hailing Carbon Products Co., Ltd. demonstrate controlled wear and steady conductivity, engineers can optimize motor cooling, torque curves, and operational noise levels. Stable wear also reduces warranty claims, improves product ratings, and helps brand owners maintain trust with consumers. By supplying household appliance carbon brushes that wear evenly across different appliance categories, Hailing supports manufacturers in delivering reliable and long-lasting home products.

FAQ

Q1: What advantages do Hailing’s household appliance carbon brushes offer?

A: With over 20 years of experience, Jiangsu Hailing Carbon Products Co., Ltd. relies on advanced equipment and independent innovation to maintain stable performance. Production follows ISO 9001 and IATF 16949 standards to ensure reliability.

Q2: Do Hailing’s carbon brushes meet environmental and safety certifications?

A: Yes. The company is certified under ISO 14001 and ISO 45001, aligning production with environmental and occupational safety requirements.

Q3: What is the monthly production capacity for household appliance carbon brushes?

A: Hailing reached a monthly output of 15 million carbon brushes in 2019, supporting the needs of large-scale appliance manufacturers.

Q4: Can Hailing customize carbon brushes for different household appliance motors?

A: Yes. Hailing collaborates with leading domestic and international motor brands and provides customized brush materials, dimensions, and performance parameters based on application requirements.

Q5: How does Hailing maintain consistent quality in mass production?

A: The company uses an advanced ERP management system and full-process quality control in accordance with ISO 9001, ensuring consistent production and stable supply.

Q6: Are the carbon brushes suitable for high-speed or high-load home appliances?

A: Through new equipment and ongoing innovation, Hailing’s carbon brushes support stable operation in applications such as vacuum cleaners, mixers, and other appliances that involve higher rotational speeds.

Q7: Does Hailing provide technical support for selecting the right carbon brush?

A: Yes. The engineering team can offer recommendations on brush grades, wear characteristics, and compatibility with specific motor designs.

Q8: What kind of brands typically choose Hailing’s carbon brushes?

A: Hailing works with many well-known domestic and international motor brands and has received “Excellent Supplier” awards for long-term cooperation.

Q9: Is Hailing qualified to serve global household appliance manufacturers?

A: Yes. The company holds High-Tech Enterprise qualification, multiple system certifications, and a trademark recognized as “Nantong Famous Trademark” and “Jiangsu Famous Trademark”, supporting its global competitiveness.

English

English 中文简体

中文简体