What is the function of treadmill carbon brushes in transmitting current in the treadmill motor?

Electrical Conduction in Treadmill Motors

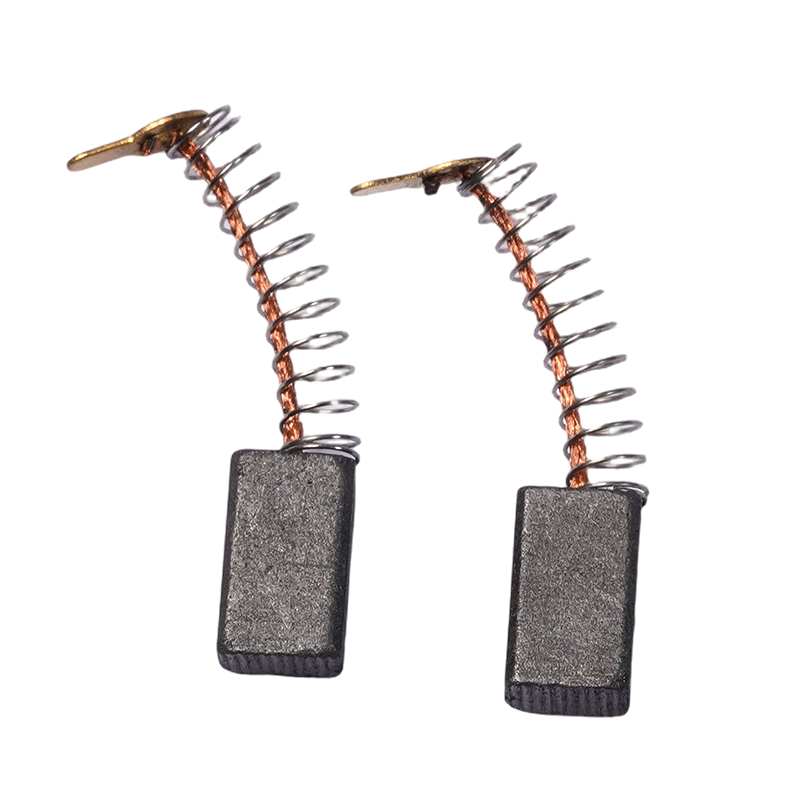

Treadmill carbon brushes serve as a critical component in transmitting electrical current from the stationary power supply to the rotating armature of the treadmill motor. The brushes maintain continuous contact with the commutator, ensuring a steady flow of current that powers the motor. Jiangsu Hailing Carbon Products Co., Ltd., with over 20 years of experience in carbon brush production, designs treadmill carbon brushes with controlled graphite composition and uniform density. This design ensures consistent conductivity and minimal electrical resistance, allowing the treadmill motor to operate smoothly during both high-speed and variable-load conditions.

Mechanical Contact and Friction Management

The function of treadmill carbon brushes extends beyond electrical conduction; they also manage mechanical friction between the rotating commutator and the stationary brush. Proper brush material and geometry reduce wear on both the brush and commutator while maintaining reliable electrical contact. Jiangsu Hailing Carbon Products Co., Ltd., utilizing advanced ERP systems and precision manufacturing, ensures that treadmill carbon brushes have optimal hardness and surface finish. This reduces the risk of uneven wear and helps maintain consistent motor performance over time.

Maintaining Motor Stability and Torque

By transmitting current effectively, treadmill carbon brushes influence the motor's torque and operational stability. Inadequate or worn brushes can lead to voltage fluctuations, reduced torque, and uneven motor rotation. Jiangsu Hailing Carbon Products Co., Ltd., recognized for its “Hailing” trademark as a Nantong Famous Trademark and Jiangsu Famous Trademark, collaborates with top domestic and international motor brands to develop brushes that maintain reliable contact and electrical transfer. This ensures treadmill motors deliver consistent speed and smooth operation under varying load conditions, contributing to user safety and exercise experience.

| Brush Feature |

Function in Current Transmission |

Company Approach |

| Graphite Composition |

Provides conductive pathway for current |

Optimized material selection and blending |

| Brush Length |

Maintains adequate contact with commutator |

Precision molding and inspection |

| Surface Finish |

Reduces friction and wear |

Controlled grinding and quality checks |

| Density |

Ensures consistent conductivity and mechanical stability |

ERP-managed production process |

Minimizing Electrical Arcing

Electrical arcing occurs when contact between treadmill carbon brushes and the commutator is inconsistent, potentially causing localized heat and accelerated wear. Jiangsu Hailing Carbon Products Co., Ltd. applies precise brush shaping and consistent material properties to reduce the likelihood of arcing. The company’s full-process quality control under ISO 9001 ensures that each treadmill carbon brush maintains uniform contact pressure and electrical conductivity, supporting the reliable transmission of current even during prolonged use.

Heat Dissipation and Operational Reliability

During treadmill operation, electrical resistance generates heat at the contact point between the carbon brush and commutator. Effective treadmill carbon brushes must conduct electricity efficiently while dissipating heat to prevent material degradation. Jiangsu Hailing Carbon Products Co., Ltd., leveraging independent innovation and advanced production equipment, optimizes graphite grade and binder composition to balance conductivity and thermal stability. These measures allow the brushes to maintain reliable performance under continuous use, ensuring that treadmill motors operate efficiently without overheating.

Wear and Maintenance Considerations

Over time, treadmill carbon brushes naturally wear due to friction and electrical load. Regular inspection of treadmill carbon brushes is important to maintain motor efficiency and prevent damage to the commutator. Jiangsu Hailing Carbon Products Co., Ltd., producing 15 million carbon brushes monthly, emphasizes predictable wear characteristics through material selection and controlled manufacturing. Proper maintenance, including timely replacement of worn brushes, helps preserve the treadmill motor's ability to transmit current effectively and maintain consistent performance throughout its service life.

| Operational Factor |

Impact on Treadmill Carbon Brushes |

Company Strategy |

| Continuous Motor Use |

Accelerates mechanical wear and heat generation |

Material optimization and thermal stability testing |

| Variable Load Conditions |

May cause uneven electrical contact |

Precision brush geometry and controlled density |

| Electrical Fluctuations |

Can induce arcing and localized heating |

Consistent conductivity and surface finish |

| Environmental Dust |

Increases friction and wear |

Controlled porosity and manufacturing hygiene |

Integration with Motor Design

Treadmill carbon brushes are designed to integrate seamlessly with the motor’s mechanical and electrical characteristics. Jiangsu Hailing Carbon Products Co., Ltd., guided by “Brand Building, Independent Innovation,” collaborates with motor manufacturers to ensure that the brush size, material, and spring pressure match the motor’s operational requirements. This integration ensures optimal current transmission, consistent torque output, and stable treadmill performance. By combining material innovation with precise manufacturing, Hailing supports treadmill motors that operate efficiently, reliably, and with predictable maintenance cycles.

Do high-power or high-speed treadmills require treadmill carbon brushes?

Role of Treadmill Carbon Brushes in High-Power Motors

High-power treadmills generate more electrical current and mechanical force within their motors compared to standard models. Treadmill carbon brushes are essential components that transmit current from the stationary power source to the rotating armature. Without these brushes, the motor cannot complete the electrical circuit, which is particularly critical in high-power applications where consistent current flow is required to drive the belt and support variable loads. Jiangsu Hailing Carbon Products Co., Ltd., with extensive experience and production capacity of 15 million brushes per month, designs treadmill carbon brushes to withstand increased electrical and mechanical stress, ensuring stable operation for high-power treadmill motors.

Function in High-Speed Operation

High-speed treadmills demand rapid rotation of the motor armature. Treadmill carbon brushes maintain continuous contact with the commutator even at elevated rotational speeds, allowing efficient electrical transfer and minimizing voltage fluctuations. Jiangsu Hailing Carbon Products Co., Ltd., through advanced equipment and independent innovation, produces treadmill carbon brushes with optimized hardness and surface finish, reducing wear while maintaining conductivity at high speeds. This ensures that treadmill motors operate reliably, supporting user safety and performance consistency during intense exercise sessions.

Material Considerations for High-Demand Usage

High-power and high-speed treadmill motors exert greater mechanical and electrical demands on treadmill carbon brushes. Material selection, including graphite grade, binder ratio, and density, directly affects brush longevity and performance. Jiangsu Hailing Carbon Products Co., Ltd., following ISO 9001 full-process quality control, ensures that treadmill carbon brushes possess uniform density, controlled porosity, and stable electrical resistance. These material properties allow the brushes to transmit current effectively while resisting accelerated wear, even under extended and high-demand operation.

| Factor |

Impact on Treadmill Carbon Brushes |

Hailing Approach |

| High Current Load |

Potential overheating and accelerated wear |

Thermally stable graphite composition |

| Rapid Rotation |

Uneven contact and electrical arcing |

Precision shaping and surface finish control |

| Continuous Operation |

Mechanical fatigue and material degradation |

Consistent density and hardness management |

| Variable Load Changes |

Voltage fluctuations and motor instability |

Optimized spring pressure and brush geometry |

Maintaining Motor Efficiency and Torque

In high-power or high-speed treadmill motors, treadmill carbon brushes play a crucial role in maintaining torque and overall motor efficiency. Worn or inadequate brushes can cause voltage drops, reduce torque, and result in inconsistent belt movement. Jiangsu Hailing Carbon Products Co., Ltd., guided by “Brand Building, Independent Innovation,” develops brushes with consistent electrical properties and precise dimensions. This ensures that treadmill motors sustain stable torque output and smooth operation, which is essential for both user experience and motor longevity.

Minimizing Electrical Arcing and Wear

High operational demands can increase the risk of electrical arcing between treadmill carbon brushes and the commutator. Arcing not only reduces motor efficiency but can also accelerate wear of both the brush and commutator. Jiangsu Hailing Carbon Products Co., Ltd., leveraging advanced manufacturing and strict quality inspections, ensures that treadmill carbon brushes maintain uniform contact pressure and controlled electrical resistance. This design approach reduces arcing, preserves motor components, and extends the effective service life of high-power and high-speed treadmill motors.

Integration with Motor Design

For high-performance treadmills, integration of treadmill carbon brushes with motor design is critical. The brush size, material composition, and spring tension must match the specific electrical and mechanical characteristics of the treadmill motor. Jiangsu Hailing Carbon Products Co., Ltd., collaborating with leading motor brands, ensures that treadmill carbon brushes are compatible with various high-power and high-speed motor configurations. This integration supports stable electrical transmission, consistent torque, and reliable motor performance under demanding conditions.

| Design Feature |

Function |

Hailing Implementation |

| Brush Size |

Maintains proper contact with commutator |

Precision molding and measurement control |

| Material Composition |

Ensures electrical conductivity and wear resistance |

Optimized graphite and binder formulation |

| Spring Tension |

Supports consistent brush pressure |

Controlled assembly and quality checks |

| Surface Finish |

Reduces friction and prevents localized heating |

Advanced grinding and inspection |

Maintenance and Replacement Recommendations

High-power and high-speed treadmill motors require regular monitoring of treadmill carbon brushes. Periodic inspection for wear, electrical arcing, and reduced motor performance is necessary to maintain efficiency and prevent damage. Jiangsu Hailing Carbon Products Co., Ltd., with ISO-certified production and an ERP-managed quality system, provides treadmill carbon brushes designed for predictable wear and consistent conductivity. Timely replacement of worn brushes ensures the treadmill motor continues to operate effectively, supporting safe, stable, and efficient performance during extended and high-demand usage.

English

English 中文简体

中文简体