What are the common causes of wear and tear on washing machine carbon brushes?

Mechanical Friction and Commutator Wear

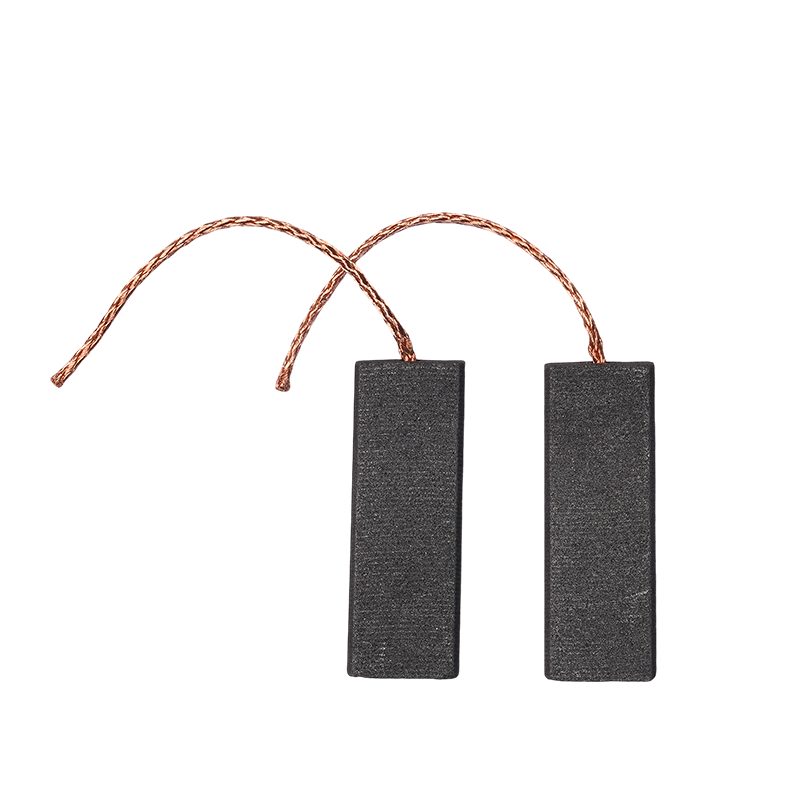

One of the primary causes of wear and tear on washing machine carbon brushes is mechanical friction with the commutator or slip rings of the motor. During operation, the brushes maintain continuous contact to transfer electrical current to the rotating armature. Over time, this friction gradually erodes the brush surface, reducing its length and potentially affecting electrical conductivity. Jiangsu Hailing Carbon Products Co., Ltd., with more than 20 years of experience in carbon brush production, applies controlled graphite selection and precise manufacturing processes to ensure consistent hardness and surface finish. These measures help washing machine carbon brushes maintain stable friction characteristics, extending service life while supporting smooth motor operation. The company’s advanced ERP system tracks production variables to guarantee uniformity across high-volume output, reducing inconsistencies that could accelerate wear.

Electrical Arcing and Sparking Effects

Electrical arcing occurs when washing machine carbon brushes fail to maintain optimal contact with the commutator, often due to vibrations, misalignment, or surface irregularities. Arcing can generate localized heat, which gradually degrades brush material and increases wear. Jiangsu Hailing Carbon Products Co., Ltd. leverages independent innovation and updated production equipment to optimize brush geometry, conductivity, and resilience. By fine-tuning material formulations and maintaining strict ISO 9001 full-process quality control, the company produces washing machine carbon brushes capable of reducing sparking frequency, improving operational stability, and supporting reliable long-term motor performance in domestic appliances.

Environmental Factors and Contaminant Exposure

Washing machine carbon brushes are exposed to environmental factors such as moisture, detergent residues, lint, and small particulate matter from laundry. These contaminants can interfere with brush performance, increasing friction, promoting uneven wear, and accelerating degradation. Jiangsu Hailing Carbon Products Co., Ltd., certified under ISO 14001 and ISO 45001, considers environmental exposure during material development. The company applies controlled porosity and density adjustments to minimize contaminant infiltration, ensuring that washing machine carbon brushes maintain structural integrity and electrical contact under typical household operating conditions.

| Wear Factor |

Impact on Washing Machine Carbon Brushes |

Preventive Measures |

| Mechanical Friction |

Gradual surface erosion and length reduction |

Optimized hardness and surface finish |

| Electrical Arcing |

Localized heat and material degradation |

Precise geometry and material formulation |

| Environmental Contaminants |

Increased friction and uneven wear |

Controlled density and porosity |

| High-Frequency Operation |

Accelerated brush consumption |

Material balancing and consistent production quality |

High-Frequency and Continuous Operation

Frequent or prolonged use of washing machines can accelerate the wear of carbon brushes. High rotational speeds and continuous operation increase the rate of abrasion and heat generation. Jiangsu Hailing Carbon Products Co., Ltd., achieving a monthly production of 15 million carbon brushes, applies lean management and rigorous quality inspections to maintain consistent material properties. Proper hardness and density combinations in washing machine carbon brushes reduce excessive wear and help preserve operational stability even under repeated load cycles. This contributes to the longevity of motors and reduces the need for frequent maintenance or replacement.

Impact of Brush Alignment and Spring Pressure

Proper alignment of washing machine carbon brushes and adequate spring pressure are critical for uniform contact with the commutator. Misalignment or uneven spring tension can result in concentrated wear at certain points, reducing brush life. Jiangsu Hailing Carbon Products Co., Ltd., guided by its principle of “Brand Building, Independent Innovation,” works with motor manufacturers to design brushes that maintain stable alignment and optimal contact pressure. Advanced ERP systems and quality certifications such as IATF 16949 ensure that brushes are manufactured to precise tolerances, supporting uniform wear distribution across the brush surface.

Material Composition and Long-Term Durability

The selection of graphite grades, copper content, and binder formulations significantly affects the wear resistance of washing machine carbon brushes. Proper material composition helps balance conductivity, mechanical strength, and friction behavior, ensuring consistent motor performance over time. Jiangsu Hailing Carbon Products Co., Ltd. combines decades of industry experience with continuous innovation to develop material blends that are resistant to abrasion, electrical wear, and environmental effects. The company’s “Hailing” trademark, recognized as a Nantong Famous Trademark and Jiangsu Famous Trademark, reflects its dedication to reliable and consistent brush manufacturing for household appliance applications.

| Brush Feature |

Role in Wear Prevention |

Industry Approach |

| Graphite Grade |

Controls mechanical and electrical friction |

Optimized material blending |

| Copper Content |

Enhances conductivity and reduces localized heating |

Consistent formulation control |

| Binder Material |

Maintains structural integrity during operation |

Precision sintering and molding |

Maintenance and Operational Recommendations

Understanding the common causes of wear and tear on washing machine carbon brushes allows for improved maintenance and operational practices. Using brushes that are correctly designed for household appliances reduces excessive wear caused by environmental factors or operational misuse. Jiangsu Hailing Carbon Products Co., Ltd., through ongoing innovation and partnerships with domestic and international motor brands, provides solutions that align material properties, design parameters, and manufacturing consistency to support longer brush life and reliable motor operation. Proper installation, periodic inspection, and attention to motor load cycles further help in mitigating brush degradation and maintaining household appliance efficiency.

Are the standard sizes of washing machine carbon brushes universal?

Variability of Washing Machine Carbon Brush Sizes

Washing machine carbon brushes are produced in a variety of sizes to accommodate different motor models and designs. While some dimensions may appear standard, the actual size requirements are influenced by the motor’s power rating, commutator diameter, and brush holder geometry. Jiangsu Hailing Carbon Products Co., Ltd., with over twenty years of experience in carbon brush manufacturing, emphasizes precision in dimensional control and material consistency. By using advanced equipment and an ERP-managed production system, the company ensures that each batch of washing machine carbon brushes meets the required specifications for specific household appliance motors. This approach reduces the risk of improper fit, which could cause uneven wear, sparking, or reduced motor efficiency.

Impact of Brush Size on Electrical Performance

The dimensions of washing machine carbon brushes directly affect electrical contact stability and current transfer. A brush that is too short or too narrow may not maintain sufficient contact with the commutator, resulting in fluctuations in motor speed or reduced torque. Conversely, oversized brushes can generate excessive friction, leading to heat buildup and accelerated wear. Jiangsu Hailing Carbon Products Co., Ltd., guided by its principles of “Brand Building, Independent Innovation,” designs and manufactures washing machine carbon brushes to balance these factors. The company’s strict adherence to ISO 9001 full-process quality control ensures that the size and shape of each brush support reliable electrical performance, even in high-cycle household appliance applications.

Standardization Efforts in the Industry

Some manufacturers attempt to standardize washing machine carbon brushes to simplify logistics and reduce inventory complexity. However, due to differences in motor design across brands and models, true universality is difficult to achieve. Jiangsu Hailing Carbon Products Co., Ltd., recognized for its “Hailing” trademark as a Nantong Famous Trademark and Jiangsu Famous Trademark, produces both standard and custom sizes. Its collaboration with domestic and international motor brands allows the company to gather data on motor specifications and operating conditions, which informs the development of brushes with appropriate dimensions for both common and specialized applications. By maintaining a flexible production approach, the company supports diverse household appliance requirements while ensuring consistent quality.

| Brush Parameter |

Effect on Motor |

Industry Approach |

| Length |

Determines contact area with commutator |

Precision molding and quality inspection |

| Width |

Affects current capacity and friction level |

Dimensional control under ERP supervision |

| Thickness |

Influences stability in brush holder |

Custom sizing for motor-specific fit |

| Spring Accommodation |

Maintains contact pressure |

Coordinated design with motor assembly |

Role of Material Selection in Size Adaptability

The ability of washing machine carbon brushes to function effectively in different sizes is influenced by material properties such as hardness, density, and conductivity. Jiangsu Hailing Carbon Products Co., Ltd. applies controlled graphite blends and binder formulations to ensure that brushes maintain consistent wear patterns regardless of slight size variations. The company’s ISO 14001 and ISO 45001 certifications support environmentally responsible production while maintaining material quality. By optimizing these parameters, Hailing ensures that washing machine carbon brushes deliver reliable performance, whether they are designed to fit common motor models or specialized units.

Manufacturing Techniques to Ensure Size Precision

Accurate sizing of washing machine carbon brushes requires precise molding, sintering, and finishing processes. Variations in temperature, pressure, or material composition during production can affect final dimensions. Jiangsu Hailing Carbon Products Co., Ltd., through its ERP-managed workflow and advanced equipment, minimizes dimensional deviations. Each batch undergoes thorough inspection for length, width, and thickness to ensure proper fit in intended motors. By combining lean management practices with rigorous testing, the company produces washing machine carbon brushes that meet both standardized and custom size requirements with consistent quality.

| Production Factor |

Impact on Brush Size |

Company Measure |

| Molding Pressure |

Affects length and width uniformity |

Controlled using automated presses |

| Sintering Temperature |

Influences dimensional stability |

Precision-controlled furnace environment |

| Material Consistency |

Determines shrinkage and density |

Batch tracking via ERP system |

| Finishing Process |

Ensures correct thickness and surface quality |

Automated grinding and inspection |

Guidelines for End Users and Maintenance

For household appliance users, understanding that washing machine carbon brushes are not fully universal helps in selecting the correct replacement. Choosing brushes that match the original motor specifications reduces the risk of accelerated wear, sparking, or motor inefficiency. Jiangsu Hailing Carbon Products Co., Ltd. provides detailed size references and collaborates with appliance manufacturers to ensure compatibility. Users benefit from brushes produced with consistent quality and precision, contributing to extended motor life and more reliable washing machine operation. Proper installation and periodic inspection also help maintain optimal performance of the washing machine carbon brushes across varying appliance models.

English

English 中文简体

中文简体