Can Carbon Brush Supplier for Motors provide ODM/OEM designs according to customer requirements?

Customization Capabilities of an OEM Carbon Brush Supplier for Motors

When discussing whether a carbon brush supplier for motors can offer ODM/OEM services, it is essential to understand how modern manufacturers structure their production capacity, research systems, and technical teams to meet customer-specific requirements. Jiangsu Hailing Carbon Products Co., Ltd., with more than 20 years of industry experience and the establishment of its 21,333㎡ new factory for Jiangsu Mincheng Carbon Technology Co., Ltd., demonstrates how a mature enterprise can support flexible and reliable customization. As an OEM carbon brush supplier for motors, the company integrates large-scale production, independent innovation, and strict quality principles to respond to various industrial design needs.

Comprehensive Engineering Support for ODM/OEM Development

For ODM/OEM customization, engineering collaboration is a core component. Jiangsu Hailing Carbon Products Co., Ltd. has accumulated profound technical expertise from its long-term focus on carbon brush development, supported by new equipment investments and innovation-driven processes. The company’s engineering team is able to evaluate motor parameters, working environments, commutation conditions, and material pairing requirements to propose structured design solutions. Whether the user needs graphite brushes, resin-bonded brushes, metal-graphite brushes, or high-density specialty formulations, the supplier can adjust material ratios, hardness levels, and dimensions based on detailed application data. This engineering capability ensures that customized carbon brushes can achieve stable contact, controlled friction performance, and suitable electrical conductivity for various motor systems.

Production Capacity Supporting Custom Carbon Brush Orders

A supplier’s production capacity determines how efficiently ODM/OEM solutions can be delivered. Hailing’s output reaching 15 million carbon brushes per month highlights its ability to manage high-volume orders while maintaining consistent standards. The new factory established in 2020 strengthens this capacity with expanded production lines, optimized workflows, and upgraded equipment. For customers requesting special brush shapes, unique wire terminals, spring assemblies, or packaging forms, the factory can create dedicated tooling and conduct small-batch pilot manufacturing before transitioning to mass production. This systematic capacity layout ensures that custom orders do not disrupt standard production while meeting delivery timelines.

Material Science Expertise for Tailored Performance

ODM/OEM customization often requires adjustments in material formulation. Jiangsu Hailing Carbon Products Co., Ltd. has leveraged its independent innovation to refine graphite grades, metal content levels, friction modifiers, and binding methods, creating a broad material library suitable for motors across industries such as home appliances, automotive, industrial machinery, and power tools. By analyzing factors such as load variation, humidity, temperature exposure, and required service life, the supplier can recommend materials aligned with customer expectations. This approach helps ensure that custom-designed brushes operate with balanced wear characteristics, controlled temperature rise, and consistent electrical interface behavior.

Process Control Ensuring Stability of OEM Carbon Brush Designs

To support reliable customized manufacturing, a supplier must have strong process control. Hailing’s factories integrate structured inspection routines—covering raw materials, semi-finished parts, and final products—to maintain uniform quality levels across custom orders. Dimensional accuracy, density consistency, and commutator contact surface finish are carefully monitored. Process stability is especially important for OEM projects because once a customized design enters mass production, repeatability becomes critical for the customer’s motor assembly line. Through optimized mixing, molding, sintering, machining, and testing processes, the supplier ensures that each batch matches the original design specifications.

Flexibility in Design Adjustments and Prototyping

ODM/OEM projects sometimes require several iterations before finalization. Jiangsu Hailing Carbon Products Co., Ltd. supports this by providing prototyping services that enable customers to evaluate brush performance in actual motor systems. Prototype units may undergo tests for wear rate, electrical resistance, commutation stability, spark behavior, and mechanical fit. Feedback from these trials allows the engineering team to modify materials or dimensions accordingly. This iterative capability is a key advantage for industries with strict performance requirements and helps customers shorten development cycles.

Collaboration and Documentation for Customer-Specific Projects

ODM/OEM cooperation involves formal technical documentation such as drawings, tolerance charts, material specifications, test reports, and quality agreements. Hailing’s long-term operational model includes structured communication channels to ensure customer requirements are accurately translated into production standards. The development process typically includes requirement confirmation, design drafting, sample production, performance verification, and final mass-production approval. This workflow ensures that customized carbon brushes integrate smoothly into the customer's motor systems while meeting traceability expectations.

Key Factors Considered in OEM/ODM Carbon Brush Customization

| Customization Factor |

Description |

| Material Composition |

Selection of graphite, resin, or metal-graphite based on electrical and mechanical requirements. |

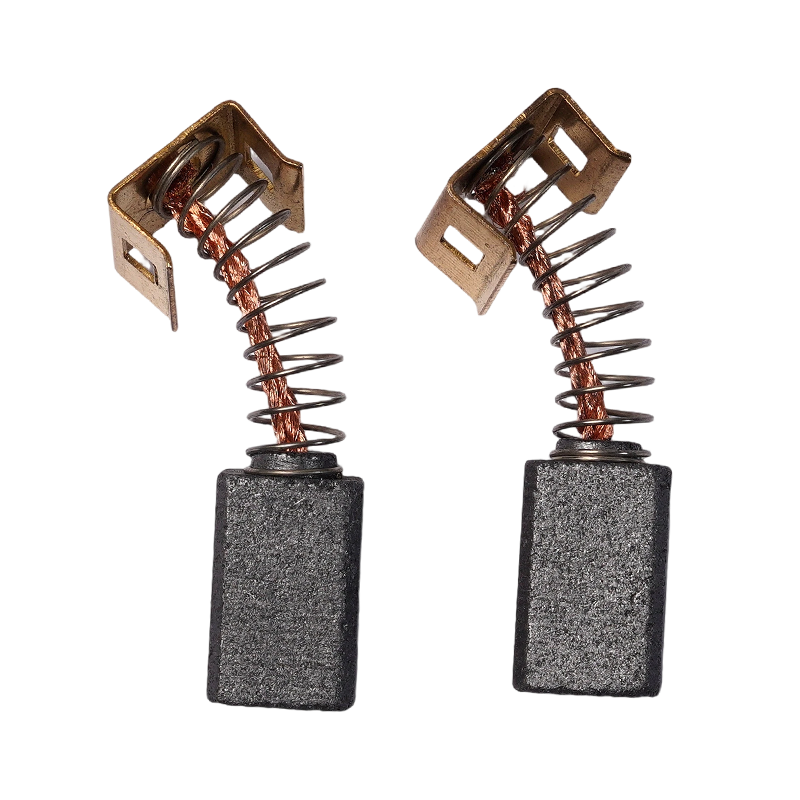

| Shape and Dimensions |

Tailored according to motor housing tolerance, brush holder size, and commutator geometry. |

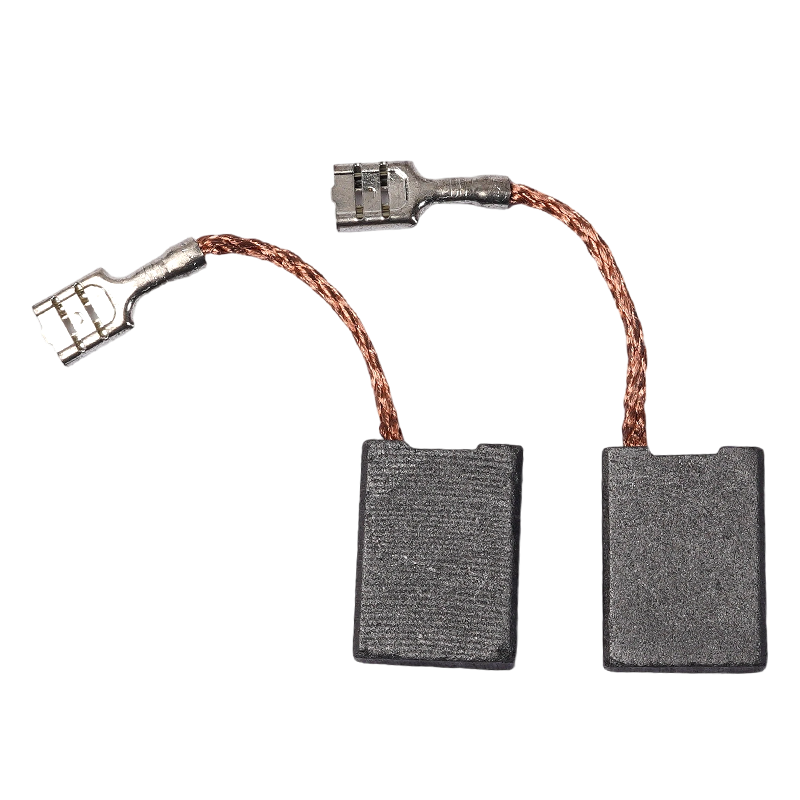

| Lead Wire Type |

Different terminals, copper wire selections, or braided connections depending on installation needs. |

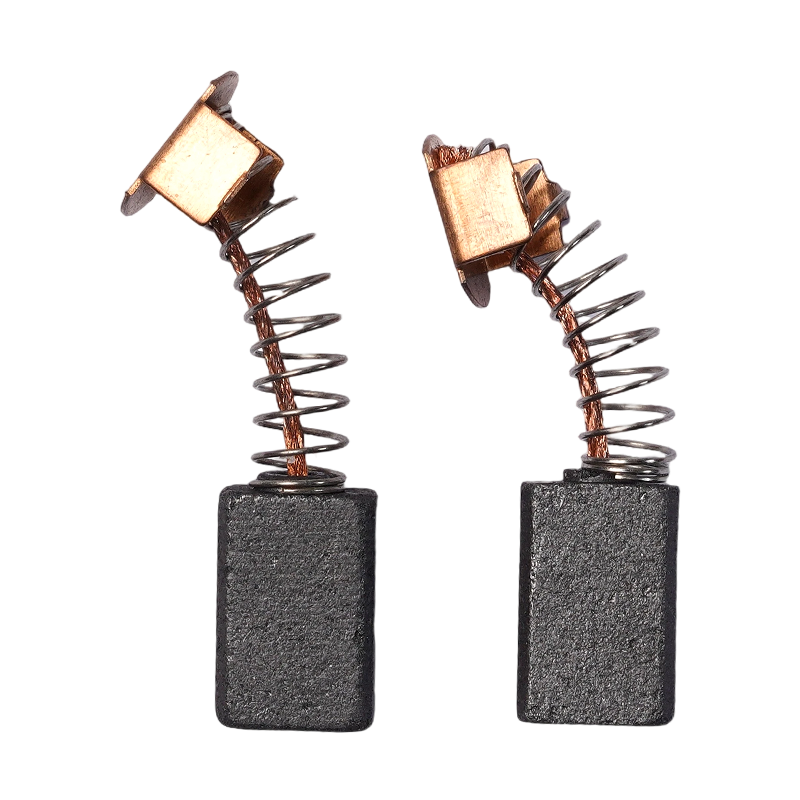

| Spring Pressure |

Pressure settings adjusted to ensure stable contact and controlled wear behavior. |

| Surface Treatment |

Grinding or chamfering customized for commutation performance and initial running-in stability. |

Long-Term Reliability Supported by Quality Principles

Jiangsu Hailing Carbon Products Co., Ltd. adheres to the principle of “Integrity in Operation, Quality First,” which guides its approach to ODM/OEM services. The company’s stable production environment, technical accumulation, and continuous facility upgrades help ensure consistent quality for customer-tailored products. With decades of specialized experience and a strong commitment to research and quality control, the supplier can deliver customized solutions that meet diverse application needs while maintaining dependable production performance.

FAQ

- Q1: What customization options does an OEM carbon brush supplier for motors provide?

OEM suppliers such as Jiangsu Hailing Carbon Products Co., Ltd. can offer customization in brush materials, dimensions, lead-wire types, spring assemblies, and surface treatments. With its advanced production equipment and expanded 21,333㎡ factory, the company can meet specialized design requirements for various motor applications.

- Q2: Can the supplier develop carbon brushes based on customer drawings or samples?

Yes. Customers can submit drawings, samples, or motor specifications, and the engineering team can create tailored carbon brush designs. With over 20 years of technical experience and independent innovation, Hailing supports both reverse engineering and collaborative development.

- Q3: What is the typical lead time for OEM carbon brush orders?

Lead time depends on customization complexity and order volume. Thanks to its large-scale production capability of 15 million pieces per month, Hailing can manage both small-batch samples and mass-production orders efficiently while maintaining stable delivery schedules.

- Q4: Does the supplier provide prototype testing before mass production?

Yes. The company can produce prototype carbon brushes for performance evaluation, including friction tests, electrical resistance checks, and running-in behavior assessments. This helps ensure compatibility with the customer’s motor system before proceeding to large-scale manufacturing.

- Q5: What industries can the OEM carbon brush supplier for motors support?

Jiangsu Hailing supplies carbon brushes for a wide range of applications, including power tools, household appliances, automotive systems, industrial motors, and generators. Its strong production capability and research support allow adaptation to diverse performance requirements.

- Q6: How does the supplier ensure quality consistency in customized designs?

Quality is maintained through strict raw material inspection, standardized processes, automated equipment, and detailed testing procedures. The company’s “Integrity in Operation, Quality First” principle ensures stable performance across all OEM orders.

- Q7: Is there a minimum order quantity (MOQ) for OEM carbon brush customization?

MOQs may vary depending on design complexity and tooling requirements. Since Hailing operates a large-scale factory, it can support flexible order quantities, including small-batch samples and full-volume production.

- Q8: Can the supplier assist with material selection for different motor types?

Yes. The engineering team evaluates operating conditions such as load, speed, temperature, and humidity to recommend suitable materials, including graphite, resin-bonded, and metal-graphite types.

- Q9: Does the supplier offer packaging customization for OEM clients?

Packaging can be customized with specific labels, batch codes, branding elements, and protective materials depending on customer requirements. This supports logistics efficiency and product traceability.

- Q10: What advantages does Hailing's new factory bring to OEM customers?

The new 21,333㎡ factory enhances production capacity, improves workflow efficiency, and supports advanced equipment integration. This strengthens the company’s ability to handle high-volume OEM orders with consistent product quality.

English

English 中文简体

中文简体