Can power tool carbon brushes maintain stable conductivity in high-speed rotating tools?

Material Stability and Electrical Conductivity of Power Tools Carbon Brushes

Power tools carbon brushes must maintain consistent conductivity to ensure smooth motor operation, especially in high-speed rotating environments. Jiangsu Hailing Carbon Products Co., Ltd., with over two decades of experience and a monthly output of 15 million carbon brushes, has established a solid production foundation for stable electrical performance. These capabilities support the development of carbon brushes that can operate under demanding conditions found in many modern power tools.

Structural Characteristics Supporting Conductivity Under High Rotation

Carbon brushes used in fast-rotating motors rely on structural uniformity and precision machining to maintain consistent electrical flow. A power tools carbon brushes factory must ensure tight dimensional control, smooth surface finishing, and appropriate density distribution to minimize electrical interruption. Jiangsu Hailing implements advanced shaping and sintering technologies that result in brushes with reliable contact stability against the commutator. These structural characteristics reduce the risk of sparking and help stabilize the contact surface even as the motor rotates at high speeds, maintaining dependable conductivity.

Heat Management and Conductivity Performance

High-speed motors generate considerable heat due to friction and electrical load. Power tools carbon brushes must therefore withstand thermal stress while preserving conductivity. Jiangsu Hailing’s material formulations balance graphite content, resin bonding strength, and metallic additives to achieve consistent electrical resistance across temperature variations. The 16,000㎡ building area dedicated to production enables large-scale thermal testing and continuous refinement of heat-resistant brush compositions. With controlled production parameters, the brushes maintain structural integrity and conductivity without sudden resistance fluctuations resulting from temperature changes.

Wear Resistance and Contact Reliability

Consistent conductivity also depends on controlled wear behavior. If wear is uneven or excessive, the contact surface becomes unstable, leading to current interruption. Jiangsu Hailing relies on independent innovation to enhance wear stability, using composite materials tailored for high-speed applications. These materials reduce debris formation and maintain a smooth interface between the brush and commutator. Through its long-term commitment to “Integrity in Operation, Quality First,” the company ensures that wear resistance aligns with the operational requirements of high-speed rotating power tool motors, supporting prolonged conductivity stability.

Testing Processes Ensuring Stable Conductivity

A structured testing system is essential to verify that carbon brushes can maintain conductivity in high-speed environments. Jiangsu Hailing conducts mechanical rotation tests, resistance stability checks, and current fluctuation evaluations to assess brush performance under load. These tests simulate different torque levels, sudden acceleration, and extended operation to verify that conductivity remains stable across conditions. Through these procedures, the power tools carbon brushes factory ensures product consistency before mass production.

| Test Type |

Purpose |

Key Evaluation Parameter |

| High-Speed Rotation Test |

Simulates rapid tool operation |

Contact stability during rotation |

| Thermal Resistance Test |

Evaluates heat tolerance |

Resistance value fluctuations |

| Wear Performance Test |

Assesses long-term brush durability |

Surface smoothness retention |

| Electrical Consistency Test |

Checks conductivity reliability |

Current continuity |

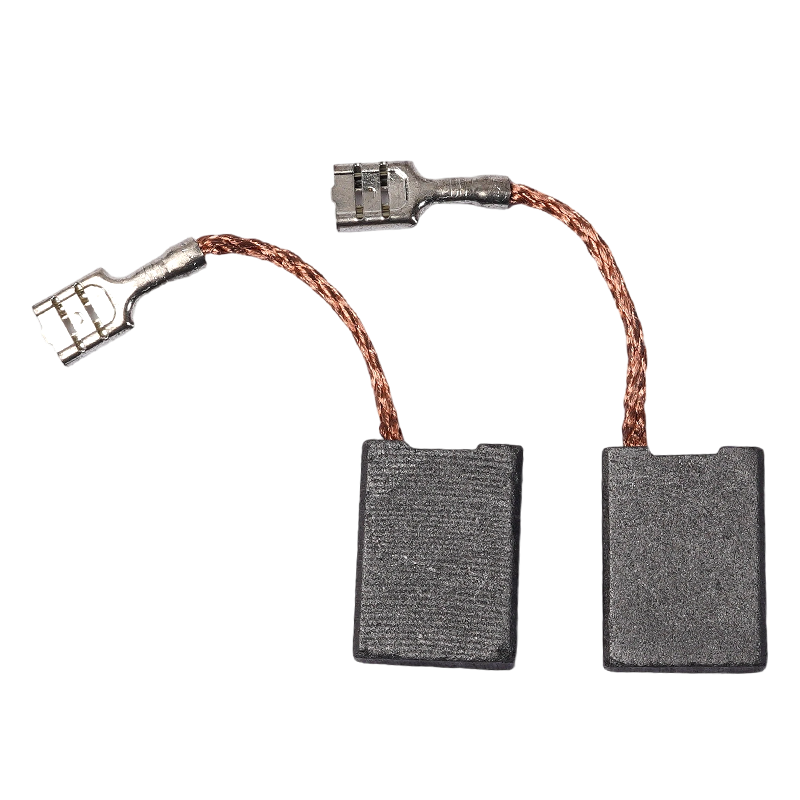

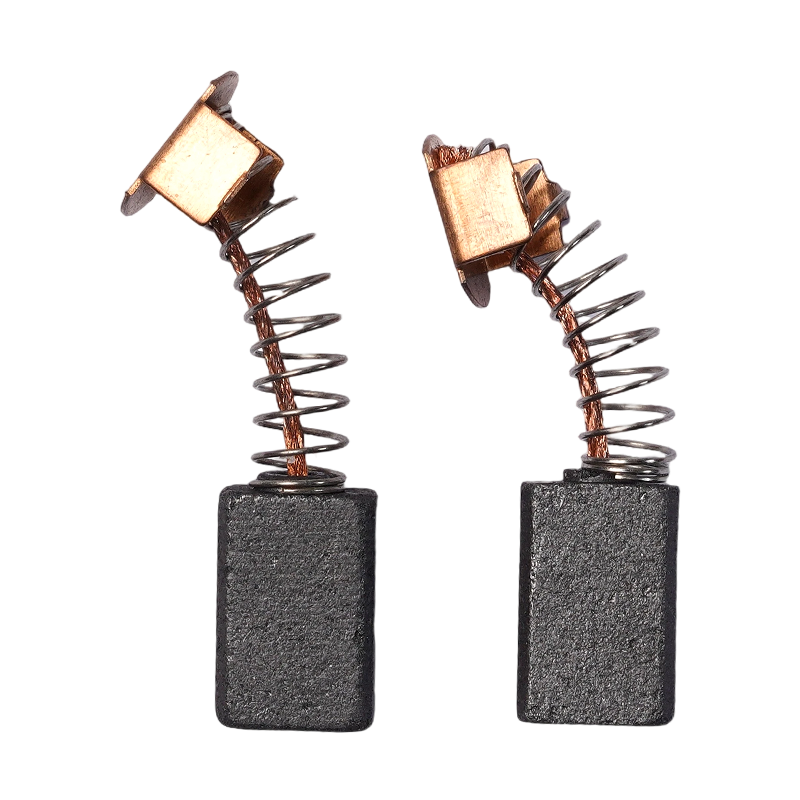

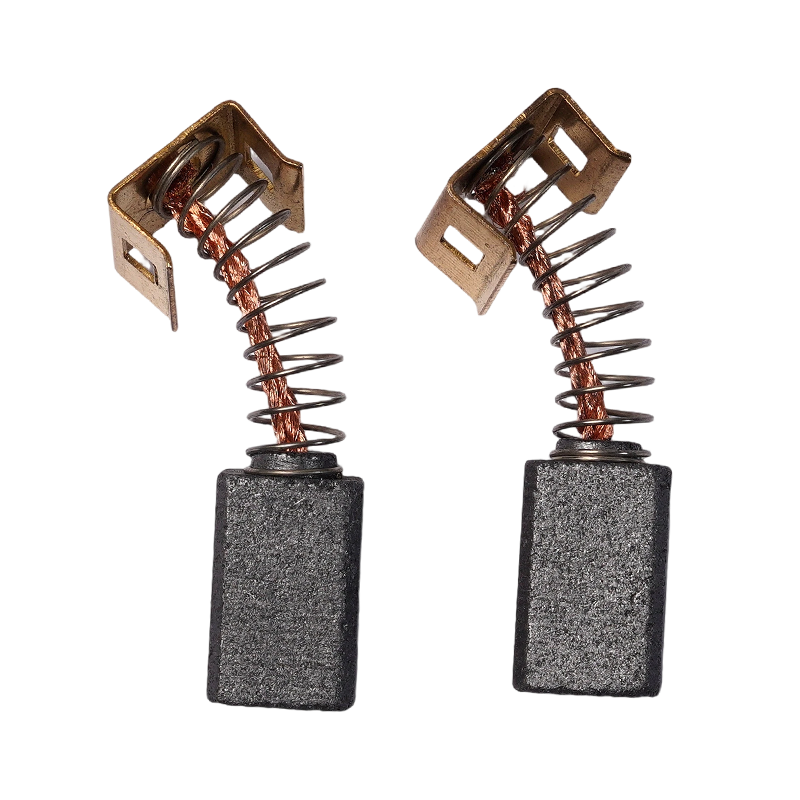

Material Selection for High-Speed Motor Applications

Different motor types require different carbon brush materials to maintain stable conductivity. Jiangsu Hailing offers graphite, resin-bonded, and metal-graphite materials tailored to specific operational speeds and loads. For high-speed rotating power tools, brushes often require a balance of conductivity and hardness to ensure stable electrical flow without causing excessive commutator wear. The company’s expanded production capability allows extensive experimentation and optimization, ensuring appropriate material matching for a broad range of power tools.

Advantages of Large-Scale Manufacturing for Conductivity Stability

Large-scale production contributes to conductivity consistency because it ensures repeatability in raw material processing and machining. With more than 300 employees and significant fixed asset investment, Jiangsu Hailing can maintain standardized production lines that minimize variation between batches. This consistency is particularly important for conductivity stability in high-speed motors, where small deviations can affect overall performance. The strength of its power tools carbon brushes factory allows the company to provide dependable products at scale.

Impact of Brush Geometry on Conductive Performance

The shape, chamfer angle, and lead-wire placement also influence conductivity in high-speed rotating motors. Jiangsu Hailing uses precision forming equipment to ensure accurate geometry, which helps maintain uniform pressure distribution between the brush and commutator. Uniform pressure reduces electrical fluctuation and helps stabilize conductivity throughout the tool’s operation. Proper geometry also supports smooth running-in behavior, reducing the time required for the brush to adapt to the commutator surface.

Conclusion on Conductivity Maintenance in High-Speed Power Tools

Overall, power tools carbon brushes can maintain stable conductivity in high-speed rotating tools when supported by refined material composition, strict quality control, and advanced processing technologies. Jiangsu Hailing Carbon Products Co., Ltd., with its new facilities, high production capacity, and long-standing commitment to stable product performance, provides the technical foundation required for carbon brushes to operate effectively in demanding power tool environments.

FAQ

Q1: Do you provide customized carbon brushes specifically designed for different power tool brands?

Yes. Jiangsu Hailing Carbon Products Co., Ltd. supports customized designs for power tools carbon brushes based on motor structure, rotational speed, and commutator specifications. With its advanced ERP system and high-standard production control, the company can match requirements from both domestic and international power tool brands.

Q2: How does your production capacity support large-scale orders for power tool manufacturers?

Hailing achieved a monthly output of 15 million carbon brushes in 2019, supported by a newly expanded 21,333㎡ factory and a 16,000㎡ production building. This capacity allows stable large-batch supply for major power tool enterprises while maintaining consistent quality.

Q3: What quality certifications do your power tools carbon brushes comply with?

The company operates under ISO 9001 full-process quality control and also holds certifications such as ISO 14001, ISO 45001, and IATF 16949. These systems ensure that every batch of power tools carbon brushes meets strict manufacturing and safety standards required by the global market.

Q4: Can your brushes maintain stable performance in high-speed rotating tools?

Yes. Hailing uses advanced material formulations and precision processing that support stable conductivity and controlled wear behavior in high-speed power tools. These technologies are strengthened by independent innovation and partnerships with top motor brands.

Q5: Do you offer OEM or ODM services for power tools carbon brushes?

The company provides complete OEM and ODM solutions, including development, testing, and production of brushes tailored to customer specifications. This is reinforced by its strong R&D capability and modernized manufacturing equipment used by Jiangsu Mincheng Carbon Technology Co., Ltd.

Q6: How do you ensure consistency across large production batches?

Hailing’s advanced ERP management system ensures precise scheduling, raw material traceability, and consistent process parameters. This systematic control minimizes variations and supports uniform performance across large volumes of power tools carbon brushes.

Q7: Are your brushes compatible with both domestic and international power tool motors?

Yes. With long-term cooperation with leading motor brands worldwide, Hailing designs carbon brushes that accommodate a wide range of tool types, voltages, and structural layouts commonly used in global markets.

Q8: Can your power tools carbon brushes reduce operational noise and vibration?

Proper material selection and surface finishing techniques help maintain smooth contact with the commutator, resulting in controlled friction and reduced vibration during tool operation. This contributes to a more stable working environment for end users.

Q9: What kind of testing do you perform before shipment?

Hailing performs resistance testing, wear simulation, balance checks, and high-speed rotation testing to ensure stable conductivity and performance. These tests follow strict internal standards aligned with its high-tech enterprise qualifications.

Q10: How does your company maintain long-term reliability in carbon brush production?

With over 20 years of industry experience, continuous equipment upgrades, and recognition such as the “Jiangsu Famous Trademark,” Hailing ensures long-term reliability in both production capability and product performance for power tools carbon brushes.

English

English 中文简体

中文简体