Do universal power tool carbon brushes affect the speed, torque, or stability of power tools?

Influence of Carbon Brush Material on Power Tool Speed

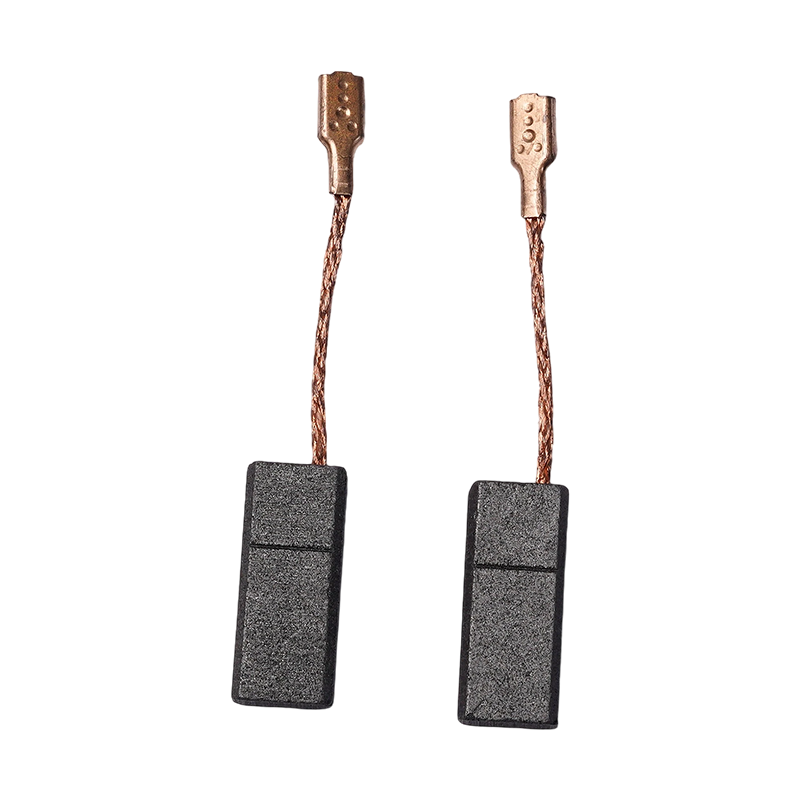

The material formulation of universal power tools carbon brushes plays a significant role in determining how effectively electrical current is transferred to the motor armature. Speed consistency in power tools depends on stable commutation, which is influenced by the brush’s conductivity, hardness, and friction characteristics. Jiangsu Hailing Carbon Products Co., Ltd., with its long-term commitment to quality and independent innovation, develops carbon brush materials through controlled blending and advanced machining techniques. These processes support smooth current flow and help reduce fluctuations that may affect speed stability during cutting, drilling, or grinding applications. The company’s ERP-driven production management ensures uniformity in brush density and dimensions, which directly contributes to motor speed consistency.

Effect on Torque Output in High-Load Working Conditions

Torque generation in power tools relies on the efficiency of energy transfer between the carbon brushes and the motor’s rotating components. When universal power tools carbon brushes maintain continuous electrical contact and minimal electrical noise, torque output remains steady even during high-load operations. Jiangsu Hailing Carbon Products Co., Ltd. incorporates precise quality control—guided by certifications such as IATF 16949 and ISO 9001—to ensure repeatable physical properties. Controlled wear behavior prevents sudden decreases in contact pressure, which could otherwise reduce torque performance. By maintaining predictable friction coefficients, the carbon brushes support consistent torque in tasks requiring stronger load handling, such as heavy drilling or material removal.

Stability of Motor Operation Under Varying Workloads

Stability is essential for power tools used in construction, electrical maintenance, woodworking, and other industrial or household scenarios. Universal power tools carbon brushes influence stability through their interaction with the commutator surface. Brushes with consistent hardness and a refined surface finish help avoid vibration or sparking, which can interrupt operation or cause uneven motor behavior. Jiangsu Hailing Carbon Products Co., Ltd. enhances stability through advanced equipment upgrades and continuous innovation, ensuring that each brush maintains structural uniformity. Its recognition as a High-Tech Enterprise and its collaborations with domestic and international motor brands support ongoing advancements that improve performance in both low-load and high-load tool applications.

| Performance Aspect |

Impact of Carbon Brush Quality |

Relevance to Power Tool Operation |

| Speed Consistency |

Stable electrical conduction |

Smoother rotation and reduced fluctuation |

| Torque Output |

Reliable brush-to-commutator contact |

Stronger load-handling capability |

| Tool Stability |

Controlled wear and reduced noise |

Fewer interruptions and more predictable operation |

| Heat Behavior |

Balanced thermal performance |

Reduced risk of overheating during long use |

Role of Manufacturing Precision in Brush Performance

Manufacturing precision is essential for achieving stable speed, torque, and operational behavior in power tools. Even small deviations in brush dimensions or density can lead to inconsistent friction or contact pressure on the commutator. Jiangsu Hailing Carbon Products Co., Ltd. uses an advanced ERP system to monitor production steps, ensuring accurate machining and material consistency across high output volumes. The company’s strong monthly production capacity—reaching 15 million carbon brushes in 2019—demonstrates its commitment to controlled, repeatable manufacturing. These production strengths help ensure that universal power tools carbon brushes meet the operational requirements of both professional-grade and consumer-grade power tools.

Impact of Wear Characteristics on Long-Term Motor Behavior

Wear characteristics of carbon brushes influence long-term tool performance. Brushes that wear too quickly can cause reduced speed or torque due to declining contact pressure, while brushes that wear unevenly may introduce vibration or instability. Jiangsu Hailing Carbon Products Co., Ltd. applies ISO 14001 and ISO 45001 environmental and occupational management standards to maintain safe and consistent production conditions. Through optimized material formulations, Hailing’s carbon brushes offer controlled wear rates that help maintain predictable motor operation during extended use. This contributes to longer maintenance intervals and fewer unexpected slowdowns in tool performance.

Heat and Electrical Noise Management in Power Tools

Power tools often operate at high speeds or under continuous load, generating heat and potential electrical noise at the commutator-brush interface. Universal power tools carbon brushes must manage these conditions without causing operational disturbances. Jiangsu Hailing Carbon Products Co., Ltd. develops carbon brushes that support balanced thermal conduction, helping prevent overheating in prolonged sessions of drilling or cutting. Its brushes are also engineered to reduce electrical noise, promoting more stable operation. The company’s independent innovation initiatives, supported by long-term cooperation with global motor manufacturers, contribute to the development of brush properties suited for varied tool applications.

| Operational Challenge |

Brush Influence |

Application Benefit |

| High-Speed Drilling |

Stable commutation and reduced friction |

Smoother speed control |

| Heavy Grinding |

Reliable torque transmission |

Improved load capability |

| Long-Duration Use |

Controlled thermal behavior |

Lower risk of overheating |

| Precision Cutting |

Reduced electrical noise |

Greater operational stability |

Contribution of Brand Reputation and Technological Strength

Brand reputation and technological capability also influence how well universal power tools carbon brushes support speed, torque, and stability. The “Hailing” trademark being recognized as both a Nantong Famous Trademark and Jiangsu Famous Trademark reflects long-term industry confidence. Jiangsu Hailing Carbon Products Co., Ltd., guided by a philosophy of “Brand Building, Independent Innovation,” integrates new materials, inspection methods, and process technologies to continuously refine brush performance. These advancements support professional users who rely on predictable tool behavior and help improve the performance stability of new-generation electric tools used in manufacturing, construction, and maintenance.

Universal Power Tool Carbon Brushes vs. Model-Specific Carbon Brushes

Differences in Application Scope Between Universal and Model-Specific Designs

Universal power tools carbon brushes are designed to fit a wide range of power tool brands and motor structures, making them suitable for general replacement needs. Their compatibility-focused structure allows distributors and service centers to stock fewer variants, reducing maintenance complexity. In contrast, model-specific carbon brushes are engineered for particular motor designs, often matching precise dimensions, spring pressure, and material formulations required by a certain tool series. Jiangsu Hailing Carbon Products Co., Ltd., leveraging more than twenty years of manufacturing experience, provides both universal and tailored carbon brush solutions supported by its advanced ERP system and strict ISO 9001 quality management. This dual capability allows Hailing to meet varying demands from global power tool manufacturers while ensuring consistent performance control during production.

Material Formulation and Its Influence on Performance

Material formulation is an essential difference separating universal from model-specific carbon brushes. Universal power tools carbon brushes generally use composite materials that offer balanced conductivity, friction stability, and wear characteristics across multiple tool types. These materials support widespread adaptability, although the formulation must accommodate diverse armature designs. Model-specific brushes, on the other hand, may incorporate specialized graphite grades, copper contents, or lubricating additives tailored to a particular motor’s load pattern. With certifications such as IATF 16949, ISO 14001, and ISO 45001, Jiangsu Hailing Carbon Products Co., Ltd. ensures rigorous testing and controlled material blending for both categories. Its wide experience in independent innovation allows the company to evaluate tool usage patterns and recommend suitable material options based on speed range, torque demand, and commutation behavior.

Impact on Motor Efficiency and Electrical Contact Stability

Stable electrical contact is necessary for consistent motor efficiency, and carbon brush choice influences this relationship. Universal power tools carbon brushes aim to provide acceptable commutation under many working conditions, maintaining dependable performance even if not optimized for one specific motor structure. Model-specific brushes may enhance electrical stability by matching the precise contact area and spring force needed for a given tool model. Jiangsu Hailing Carbon Products Co., Ltd., recognized with “Excellent Supplier” awards and known for its cooperation with domestic and international motor brands, conducts detailed commutation tests to identify correct brush-to-commutator interactions. Through controlled production supported by advanced equipment, Hailing ensures that both universal and customized designs maintain consistent electrical behavior suitable for long-term tool operation.

| Aspect |

Universal Power Tool Brushes |

Model-Specific Brushes |

| Compatibility |

Broad, fits many tool models |

Narrow, designed for exact models |

| Material Optimization |

General-purpose formulation |

Custom-tailored formulation |

| Maintenance Convenience |

Easy to source and replace |

Precise fit, may require exact matching |

| Performance Tuning |

Suitable for general tasks |

Tuned for specific load patterns |

Durability and Wear Characteristics Under Continuous Use

Durability is influenced by load cycles, friction stability, and heat generation during prolonged operation. Universal power tools carbon brushes are designed to offer stable wear behavior across different brush holder designs and commutator materials, providing dependable performance for users who frequently switch between tool brands. Model-specific brushes often achieve more predictable wear patterns because they align precisely with motor geometry. Jiangsu Hailing Carbon Products Co., Ltd., with a monthly production capacity exceeding fifteen million brushes in 2019, applies its lean management practices to ensure controlled surface treatment and uniform density distribution. These production strengths help maintain measured wear behavior, supporting both universal and model-specific options in long-running operations.

Heat Management and Motor Protection Features

Heat generation occurs naturally at the commutator-brush interface, and brush design determines how effectively this heat is managed. Universal power tools carbon brushes incorporate balanced thermal conduction characteristics, allowing them to perform across tools with different heat dissipation structures. Model-specific brushes may integrate properties that match the motor’s internal cooling system, further supporting long-duration operation. Jiangsu Hailing Carbon Products Co., Ltd., recognized as a High-Tech Enterprise, conducts thermal rise tests and evaluates brush-film formation to assess heat control performance. These assessments help determine whether universal or tailored brushes are more appropriate for high-speed tools used in drilling, cutting, or grinding environments.

| Performance Factor |

Universal Brushes |

Model-Specific Brushes |

| Heat Dissipation |

Balanced for broad adaptability |

Aligned with tool-specific cooling |

| Wear Rate Predictability |

Moderately predictable |

Highly predictable with exact match |

| Electrical Noise |

Controlled for general use |

Optimized for specific designs |

| Sparking Behavior |

Minimized under broad conditions |

Tuned to reduce sparking for a specific motor |

Selection Considerations for Manufacturers and End Users

When choosing between universal power tools carbon brushes and model-specific variants, tool manufacturers and users must evaluate operational requirements, replacement convenience, and performance stability. Universal brushes are beneficial for aftermarket distribution, repair centers, and users who prefer simplified maintenance across multiple tool brands. Model-specific brushes are more suitable for professional applications requiring stable speed behavior, more consistent torque, and predictable long-term wear patterns. Jiangsu Hailing Carbon Products Co., Ltd., with its trademark recognized both in Jiangsu and Nantong, incorporates practical feedback from global motor partners to refine both brush types. By continuously advancing materials research and adopting lean management, Hailing ensures its brush solutions support the variable needs of the modern power tool industry.

English

English 中文简体

中文简体