What Specific Material Properties and Dimensional Controls are Essential for Ensuring High-Volume Power Tools Carbon Brushes Provide Consistent Performance and Consumer Safety?

Power tools utilized in consumer and prosumer environments, such as those manufactured by B&D, demand carbon brushes that blend cost-efficiency with uncompromising safety and reliability. These tools often experience intermittent use cycles, rapid start-ups, and varying load conditions. Power Tools Carbon Brushes serve as the essential electrical contact, requiring a material composition and manufacturing precision that ensure optimal electrical transfer and predictable wear life.

Material Selection for Consistency and Value:

The material matrix must be specifically formulated to manage moderate current densities and high peripheral speeds while being robust enough to handle the dusty environments typical of DIY and professional job sites.

Graphitic and Carbon-Graphite Grades: For drills, sanders, and smaller routers, standardized graphitic or carbon-graphite grades are frequently employed. These materials are characterized by their high purity and low ash content, which helps to minimize abrasive wear on the motor commutator. These grades are synthesized through a rigorous thermal treatment that optimizes the carbon structure for inherent lubricity. This self-lubricating property is crucial for reducing friction, minimizing operational heat, and ensuring smooth operation across the tool's intended lifespan. The consistency of this base material is a critical focus for Wholesale Power Tools Carbon Brushes For B&D Manufacturers operating in high-volume supply chains. The thermal treatment process, known as graphitization, is precisely controlled to develop a stable, crystalline carbon structure that resists premature breakdown.

Powder Metallurgy for Specialized Grades: For applications requiring higher current capacity, such as angle grinders, advanced powder metallurgy techniques are used. Finely ground metal powders, often copper or bronze, are uniformly blended with the graphite base. This mixture is then compacted under high pressure and sintered at elevated temperatures. This process creates a dense, homogeneous metal-graphite composite. The metallic component ensures superior electrical conductivity and efficient heat transfer away from the contact face, supporting higher intermittent loads. The careful management of particle size and distribution is vital to ensure that the conductive metallic elements do not compromise the graphite's critical lubricating function, preserving both electrical and mechanical integrity.

Resin-Bonded Stabilization: To enhance the mechanical integrity of the graphite structure, particularly important for brushes subject to the vibration of jigsaws and reciprocating tools, specialized thermosetting resins are incorporated. These binders significantly increase the material's modulus of elasticity and fracture resistance, preventing premature chipping or structural degradation under mechanical stress. The careful control of the resin content ensures that the brush remains conductive and maintains its intended wear rate, which is a key measure of long-lasting durability. The resin systems are chosen for their thermal stability, ensuring they do not soften or smoke when the tool is operated continuously under load, maintaining consistent contact pressure and preventing the formation of detrimental deposits on the commutator.

Commutation Film Management and Environmental Response: Successful brush performance hinges on the stable formation of a protective patina, or film, on the copper commutator. Brushes designed as Power Tools Carbon Brushes For B&D are formulated to rapidly establish this micron-thin layer. This film acts as a boundary lubricant and a critical electrical interface, mitigating arcing and reducing wear. The composition includes trace elements that actively manage the chemical environment at the contact surface, promoting film stability even when the tool is stored for long periods between uses or operated in high humidity. Environmental factors, such as ambient moisture, can dramatically affect the friction coefficient and film formation, necessitating a brush composition engineered for wide climatic resilience.

Dimensional Precision for Universal Fitment:

Given that many power tool brushes are sold as high-volume aftermarket replacement parts, maintaining extremely tight dimensional tolerances is paramount.

Micron-Level Control: The carbon block dimensions are controlled with precision often below 50 micrometers. This accuracy ensures the brush moves smoothly within the motor's brush holder channel, preventing sticking or jamming. A brush that sticks will not maintain contact pressure, leading to dangerous sparking, rapid commutator damage, and premature motor failure. The specific parallelism and squareness tolerances are validated using advanced digital metrology systems to ensure repeatable fitment across millions of units.

Geometrical Accuracy and Run-In Profile: The parallelism of the contact face and the squareness of the sides are critical for ensuring the brush makes full, uniform contact with the commutator. Precision grinding techniques are used to achieve this geometry, reducing initial run-in time and immediately promoting reliable conductivity from the moment of installation. Some brush faces are manufactured with specific contours or beveled edges to optimize the initial contact patch and accelerate the uniform development of the commutator film, supporting smooth operation from the first use.

How Do Brush Assembly Features and Quality Management Systems Guarantee Reliability and Maintain Low-Cost Maintenance in B&D Tool Systems?

The long-term value and safety of power tool components are fundamentally linked to the mechanical assembly and the consistency delivered by the supply chain. For high-volume tools, every component must integrate seamlessly and reliably.

Assembly Engineering for Durability:

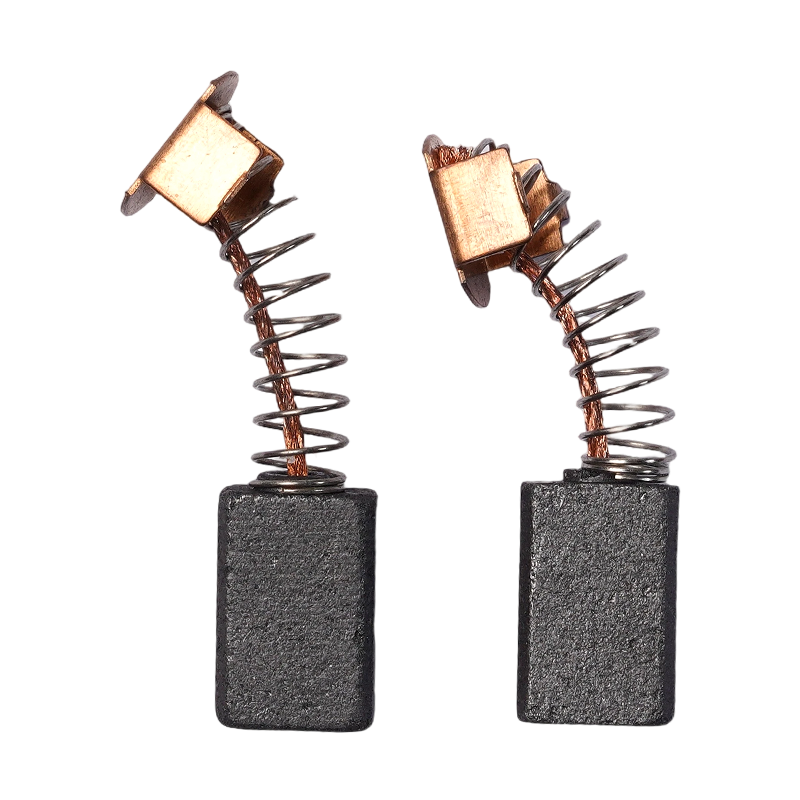

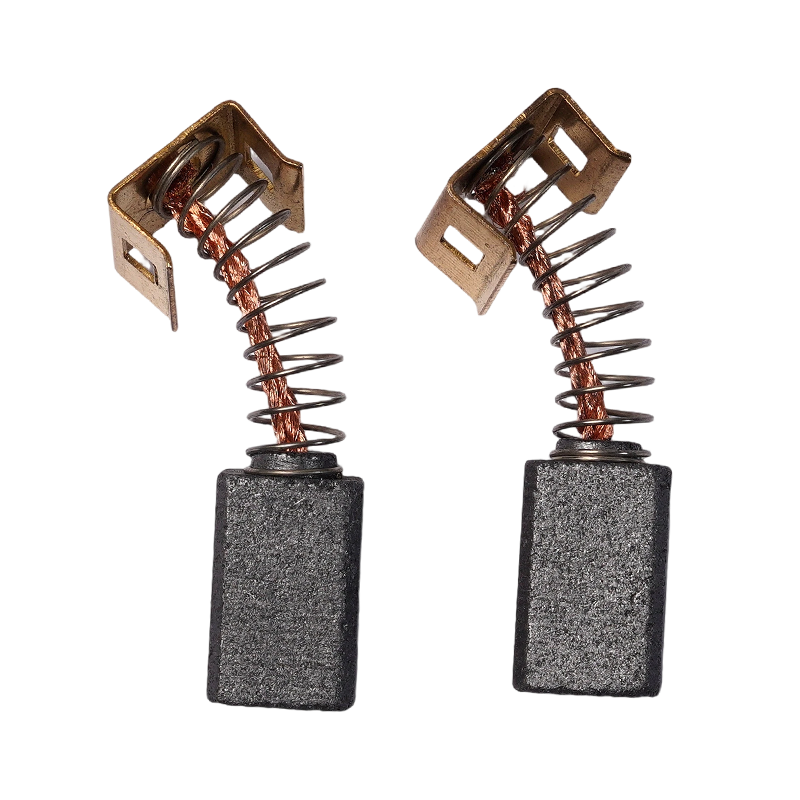

The non-carbon parts of the assembly are engineered to be as robust as the carbon block itself.

Pigtail Attachment Integrity and Fatigue Resistance: The copper shunt, or pigtail, must handle the full load current without excessive heat buildup and must resist mechanical fatigue from motor vibration and brush movement. Advanced manufacturers use high-temperature brazing or specialized low-resistance welding to create a permanent, gas-tight bond between the pigtail and the carbon block. This ensures that the electrical connection maintains reliable conductivity and does not degrade under the thermal cycling of intermittent use. The pigtail itself is typically made of high-strand, flexible copper cable, specifically chosen for its resistance to bending fatigue and its ability to withstand constant movement as the brush wears down, supporting long-lasting durability.

Auto-Stop Mechanism for Safety: A key feature in professional-grade brushes is the integrated auto-stop mechanism. This safety feature uses a small metallic contact embedded within the brush body. When the brush wears down to its minimum safe length, the circuit is deliberately broken, instantaneously shutting off the motor. This prevents the spring or brush holder metal from contacting the high-speed commutator, which is a major safety hazard and cause of irreparable motor damage. This feature ensures that the brush serves as a clear, proactive warning and maintenance indicator, supporting the overall long-lasting durability of the tool system.

Optimized Spring Systems and Consistent Pressure: The spring mechanism is essential for delivering uniform contact pressure across the entire life of the brush. Manufacturers utilize high-fatigue spring steel alloys to ensure the spring force remains consistent as the brush wears down. This constant pressure prevents brush bounce and chatter, which are primary causes of sparking and accelerated wear, thereby guaranteeing reliable motor performance. The spring's force curve is meticulously calibrated to ensure the optimal balance between minimizing friction and maintaining sufficient pressure for stable current transfer across the full working stroke.

Quality Management and Manufacturing Advantage:

The consistency and reliability of Power Tools Carbon Brushes For B&D at scale are driven by stringent manufacturing processes and integrated quality control systems.

A prominent manufacturer in this specialized field, Jiangsu Hailing Carbon Products Co., Ltd., is a leading China Carbon Brushes For B&D Manufacturers that adheres rigorously to the "Integrity in Operation, Quality First" philosophy. The manufacturer leverages advanced production techniques and integrated quality management systems to ensure product performance. The utilization of an advanced ERP system in production is fundamental to their operation, allowing for stringent, real-time management of batch consistency. This digital platform ensures end-to-end traceability, from validating the precise raw material mixture ratio to documenting the exact sintering temperature curve for every batch. This systemic control is crucial for producing high-reliability products at scale and maintaining component uniformity across large tool lineups. This systemic focus on consistent quality has enabled them to achieve high-volume output while partnering with top domestic and international motor brands, ensuring their Wholesale Power Tools Carbon Brushes For B&D Manufacturers remain highly competitive in the global market.

Performance Validation for Reliability:

Rigorous testing protocols ensure the brushes can withstand the stresses of real-world power tool usage.

High-Speed Wear and Life Testing: Brushes are mounted on customized test rigs that simulate the maximum rotational speed and rated current of the intended application. Data collected, including precise wear rate measurement and continuous monitoring of contact voltage stability, is critical for accurately predicting the service life of the brush. This allows end-users and distributors to manage inventory and replacement schedules effectively, guaranteeing reliable motor performance.

Commutation Stability and Noise Monitoring: Specialized electrical analysis equipment is used to monitor the quality of current transfer during rapid acceleration and deceleration cycles. The degree of arcing and electrical noise, specifically radio frequency interference RFI, is meticulously measured. This testing ensures the brush material delivers stable commutation across the full operating range, which is directly correlated with maintaining smooth operation and long-term motor health. Low electrical noise is also a prerequisite for compliance with international electromagnetic compatibility standards.

Vibration Analysis and Mechanical Integrity: Brushes are subjected to controlled, high-frequency vibration testing that simulates the mechanical loads experienced by impact and rotary tools. This test validates the mechanical integrity of the carbon block and, critically, the fatigue resistance of the pigtail attachment. This ensures that the assembly will not fail prematurely due to physical stress, contributing significantly to long-lasting durability.

Product Specification Reference for B&D Tools:

|

Brush Application Profile

|

Primary Material Grade Type

|

Commutation Demand Focus

|

Durability and Maintenance Feature

|

|

High-Speed Drills and Routers

|

High-Purity Electrographite

|

Optimized for Low Acoustic and Electrical Noise

|

Designed for Low Friction and Smooth Operation across the full wear life

|

|

Standard Angle Grinders

|

Medium Copper-Graphite Composite

|

High Intermittent Current Handling and Heat Dissipation

|

Features High Thermal Stability and Reliable Conductivity under heavy load

|

|

Reciprocating Saws and Jigsaws

|

Advanced Resin-Bonded Carbon-Graphite

|

Superior Resistance to Mechanical Shock and Tool Vibration

|

Possesses Enhanced Mechanical Strength for Long-lasting Durability in demanding cycles

|

|

Heavy-Duty Compact Tools

|

Specialized Metal-Graphite Composite

|

Maximum Power Transfer Efficiency during High Torque Starts

|

Engineered for High Resistance to Arcing and Wear for consistent reliable motor performance

|

The commitment to precise material formulation and consistent, high-volume manufacturing, underpinned by comprehensive quality management, ensures that these specialized Grinder Carbon Brushes For B&D Suppliers provide components that meet the demanding standards for safety, performance, and durability in the global power tool market.

English

English 中文简体

中文简体