What Commutation Principles and Electrical Parameters are Optimized for High-Speed Power Tool Carbon Brushes?

The heart of every universal motor in HITACHI power tools lies in the precise management of current transfer, known as commutation. This process, where the current direction is reversed in the armature coils, is inherently chaotic and must be strictly controlled by the Power Tools Carbon Brushes to ensure efficiency and longevity. Poor commutation leads to excessive sparking, motor overheating, and rapid failure of both the brush and the commutator. Therefore, Original Hitachi Tools Carbon Brushes Manufacturers focus intensively on optimizing electrical parameters to handle the high rotational speeds and transient loads typical of professional equipment like angle grinders and impact drills.

Commutation Fundamentals in Universal Motors:

Universal motors operate on both AC and DC, demanding a brush design that performs optimally across a wide frequency and voltage spectrum. Effective commutation hinges on several critical electrical parameters. The instantaneous contact voltage drop across the brush-commutator interface must be low enough to minimize power loss and heat generation, but high enough to effectively oppose the reactive voltage generated in the armature coils during current reversal. This delicate balance prevents destructive circulating currents and excessive sparking. Grades designed for power tool use, such as those utilized in high-RPM drills, feature tailored resistivity that is precisely achieved through controlled thermal processing of the raw carbon material. This specific resistivity ensures a stable contact drop, typically targeted between 1.0 and 2.5 volts per brush pair, a range empirically proven to yield the most stable and efficient power transfer under dynamic load.

Optimizing Contact Drop and Energy Transfer:

Contact drop is the voltage loss that occurs as current passes from the brush to the commutator. For high-power tools, minimizing energy waste while maintaining commutation quality is paramount. Power Tools Carbon Brushes grades achieve this through the inclusion of specialized metallic fillers in metal graphite grades, often copper or bronze, which dramatically increase bulk conductivity. The challenge is ensuring these conductive elements do not compromise the lubricating properties of the graphite. Manufacturers use ultra-fine powder metallurgy, blending materials at the nanoscale to ensure a homogeneous matrix where the graphite's lubricating layer is maintained despite the high metallic content. This advanced blend promotes efficient current passage, supports higher intermittent current densities and significantly reduces the I²R losses, directly translating to less heat generation in the brush itself. The resulting low internal resistance is a hallmark of an Original Hitachi Tool's Quality Carbon Brush.

Advanced Material Science for Low Resistivity Grades:

The base material for high-performance brushes is often high-purity carbon refined through extreme thermal processes. Electrographitic brushes are subjected to temperatures over 2500 degrees Celsius, which transforms the amorphous carbon into a highly ordered, crystalline graphite structure. This deep graphitization is not only responsible for superior electrical conductivity but also provides a structure with enhanced resistance to thermal fatigue. For tools with high momentary load peaks, such as rotary hammers, the material must also possess high mechanical integrity. Specialized binder resins are utilized to reinforce the graphite structure without detrimentally increasing resistivity. These thermosetting agents create a composite that is highly resistant to fracture, chipping, and mechanical degradation under severe impact and vibration, key features for Grinder Carbon Brushes For HITACHI Suppliers where robust mechanical survival is crucial.

The Role of Surface Patina and Film Stability:

The commutator film, or patina, is the micron-thin oxide and graphite layer formed on the commutator surface by the friction and chemistry of the brush material. This film is the true electrical interface, and its stability directly determines the motor's lifespan. Power Tools Carbon Brushes For HITACHI are formulated with specific components that promote the rapid formation of a dense, stable film, even during high-speed, high-current operation. This film is designed to be slightly harder than the brush material itself, which aids in gently polishing the copper commutator, preventing the formation of ridges and grooves. The inclusion of trace inorganic additives, often measured in parts per million, actively manages the chemical reaction at the contact surface, ensuring the film remains uniform and conductive under varying atmospheric conditions like humidity and temperature swings often encountered on job sites.

The manufacturer, Jiangsu Hailing Carbon Products Co., Ltd., is a leading China Carbon Brushes For HITACHI Manufacturers that maintains its competitive edge through a strict adherence to its "Integrity in Operation, Quality First" philosophy. Their production excellence is supported by an advanced ERP system, which provides real-time oversight and end-to-end traceability of material batches. This systemic control is fundamental to ensuring that every single brush produced adheres to the precise formulation and dimensional tolerance required for optimal commutation, guaranteeing consistency in complex electrical parameters like contact drop and resistivity across their high-volume output.

How is the Thermal and Mechanical Integrity of Power Tool Carbon Brushes Validated for Long-Term Reliability?

The operational lifetime of Power Tools Carbon Brushes is not solely determined by electrical efficiency, but equally by their ability to manage extreme thermal load and survive sustained mechanical abuse. Professional power tools generate significant heat and vibration, requiring specialized engineering in the brush assembly to ensure long-lasting durability.

Thermal Dissipation Strategies in Confined Casings:

The small, enclosed nature of power tool motor housings restricts airflow and heat dissipation, placing a high thermal burden on the Power Tools Carbon Brushes. Materials are selected specifically for their high thermal conductivity, allowing heat generated at the contact face to be rapidly conducted away into the brush body and pigtail shunt. For metal graphite grades, the high copper content serves the dual purpose of enhancing electrical conductivity and acting as a heat sink. In some electrographitic designs, specialized binding agents that maintain structural integrity up to 200 degrees Celsius are employed. Furthermore, the design of the pigtail connection is optimized not just for current transfer, but as a critical thermal pathway, efficiently transferring heat from the brush block to the brush holder and casing, mitigating the risk of thermal runaway.

Mechanical Shock Resistance and High G-Force Survival:

Power tools are subject to frequent dropping, impact, and high-frequency vibration during operation, particularly percussion tools like rotary hammers. The brush material must possess exceptional mechanical strength to resist fracturing. Specialized high-strength electrographitic grades, reinforced with high-modulus binders, are used to maximize resistance to chipping or breaking, preventing catastrophic failure when the tool is subjected to physical shock. The density and porosity of the finished carbon block are precisely controlled to provide inherent dampening properties, absorbing kinetic energy and reducing the transmission of high-frequency motor vibration to the commutator surface, which is critical for maintaining smooth operation and preventing chatter-induced sparking.

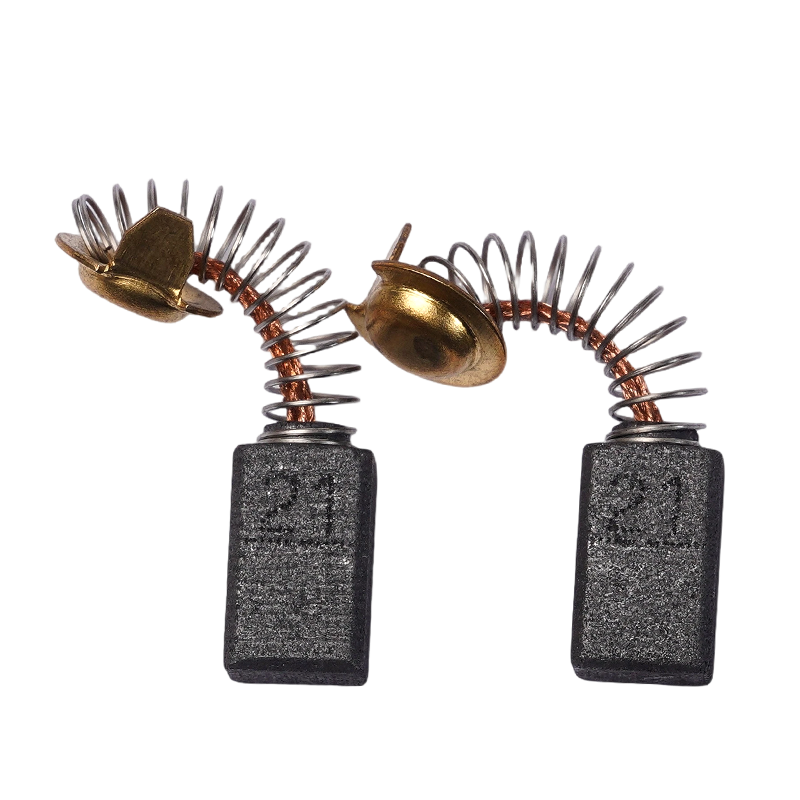

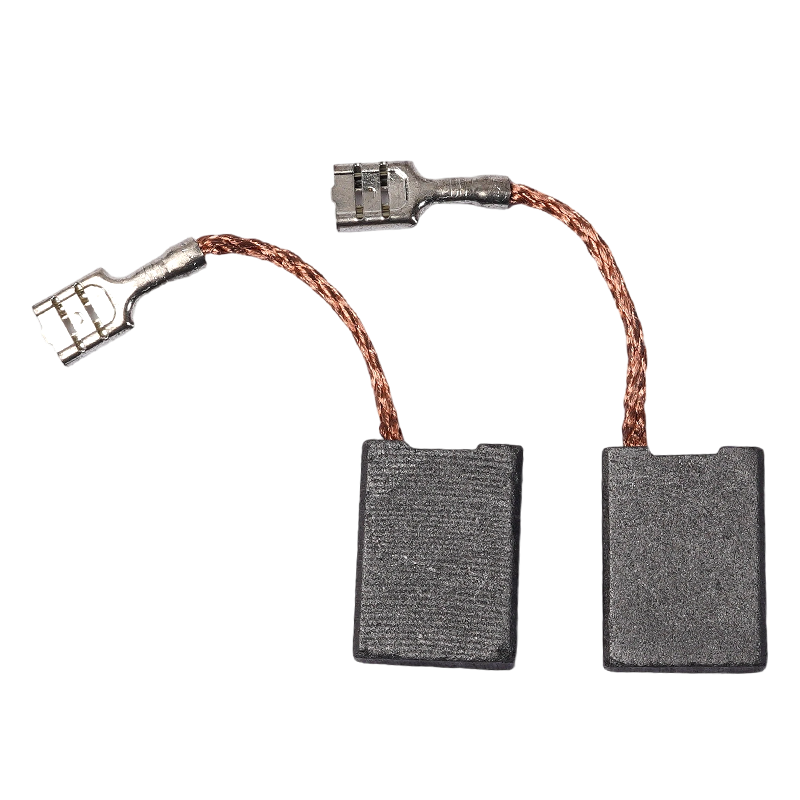

Pigtail Brazing and Strain Relief Design:

The copper pigtail connection is structurally the weakest point in the assembly, constantly flexing as the brush travels. The quality of the weld or braze connecting the shunt to the carbon block is paramount to reliable conductivity and mechanical survival. Advanced induction brazing techniques are used to create a permanent, low-resistance metallurgical bond that exhibits high resistance to thermal cycling and physical fatigue. Additionally, the pigtail cable itself is designed with strain relief features either specialized insulating boots or precise looping to manage stress concentration points, ensuring the connection does not fail due to bending fatigue before the brush material is fully consumed. The specification of the pigtail is often a high-strand, silver-plated copper wire to maximize flexibility and corrosion resistance.

Advanced Life Cycle Modeling and Predictive Failure Analysis:

To guarantee long-lasting durability and consistent performance, manufacturers employ rigorous predictive testing regimes. Brushes are subjected to highly accelerated life testing on customized dynos that accurately simulate the current, voltage, and vibrational profile of specific HITACHI tools under overload conditions. This allows engineers to condense years of field use into weeks of laboratory testing. Data collected, including wear rate measurement, contact voltage stability monitoring, and thermal profiling, is fed into advanced predictive failure models. These models accurately forecast the brush's service life, enabling motor brands to set accurate replacement intervals and ensuring users benefit from reliable motor performance over the entire expected life of the product. Beyond material wear, the models specifically track the degradation rate of the auto-stop sensor to ensure it triggers accurately at the predetermined minimum wear length.

Integrated Safety Features:

A key mechanical design feature for protecting the motor and user is the auto-stop mechanism. This integrated feature, mandatory in many professional Power Tools Carbon Brushes, relies on a small conductive element embedded within the brush body. When the brush wears down to a critical predefined limit, the circuit is physically broken, instantly shutting off the motor. This prevents the spring or other metal components of the brush holder from contacting the high-speed commutator, which would cause severe arcing and motor destruction. The actuation point of this mechanism is controlled with micron-level precision during the final assembly process, ensuring the safety device is both reliable and accurate throughout the brush's entire operational life.

The expertise demonstrated in material science, combined with an unwavering focus on mechanical precision and electrical stability, ensures that these specialized Grinder Carbon Brushes For HITACHI Suppliers meet the stringent performance and durability requirements of the professional global power tools market.

English

English 中文简体

中文简体